Dust fire prevention systems

Sinto offers systems built from a variety of fire prevention devices developed through our unique expertise in the field.

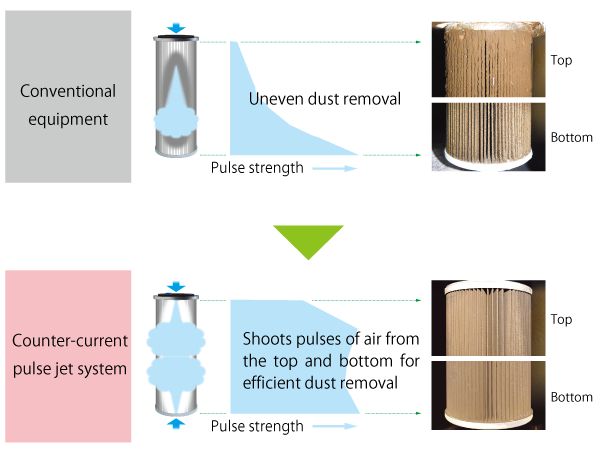

CONCEPT1 - Remove dust completelyCounter-current pulse jet system

Filter surfaces are covered with flammable dust

The conventional method of cleaning filters with compressed air does not sweep dust away evenly. Sinto’s proprietary counter-current pulse jet system, however, shoots compressed air from jets mounted above and below cartridge filters, evenly cleaning the entire filter surface.

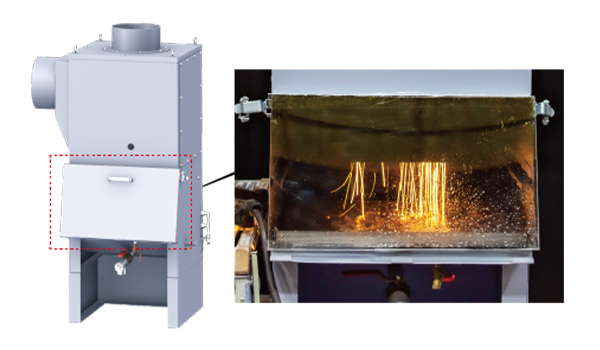

CONCEPT2 - Eliminate sparksWet chamber

Water is used to eliminate sparks that can cause dust fires

Water is used to remove sparks before they can be sucked into the dust collector. This setup delivers better extinguishing performance than gravity settling or cyclone devices.

Note: Cannot be used with aluminum or other water-reactive particles

▲Wet surface extinguishes sparks

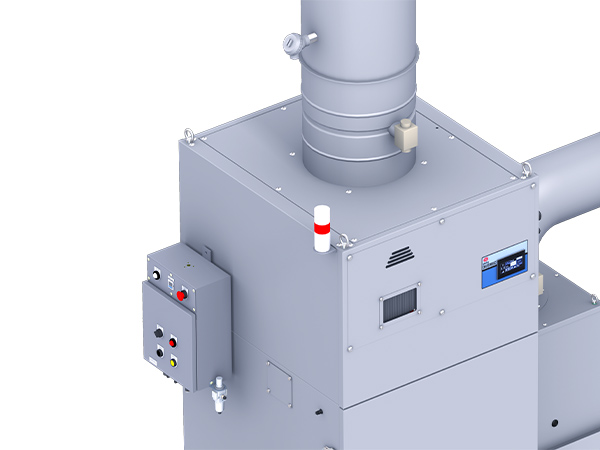

CONCEPT3 - Detect fires quicklyEarly fire detection system

Quick detection and warning

These devices identify filter burns and dust leaks, putting out a signal and lighting a warning lamp when abnormalities are detected.

▲Early fire detection system and sensor

CONCEPT4 - Prevent fire from spreadingFire-resistant filters

Filters with exceptional fire resistance

Simply changing out the filters in a Sinto dust collector is a powerful fire prevention step.

We offer a lineup of fire-resistant filters designed to prevent static electricity buildup, which can be a major cause of sparks.

▲Filter material fire-spreading test

CONCEPT5 - Extinguish fires safely

Prevent secondary disasters

Heat-resistant internal monitoring window

A heat-resistant glass window lets you check to make sure that fires are out.

Fire extinguisher port

Once the fire has calmed, a fire extinguisher can be inserted into the machine without opening the inspection door.

Inert gas blower

Blows inert gas (such as N2) into the dust collector to prevent fire from spreading.

(Note: Requires a separate inert gas tank and external piping)

Intake/exhaust cutoff damper

Automatically cuts off the intake/exhaust ports on the dust collector when a fire breaks out to prevent outside air from getting in.

Pulse air tank/air release valve

Air tank stores compressed air for the pulse valve. The compressed air can be released outside of the machine to minimize the supply of oxygen inside.

▲Heat-resistant internal monitoring window and fire extinguisher port

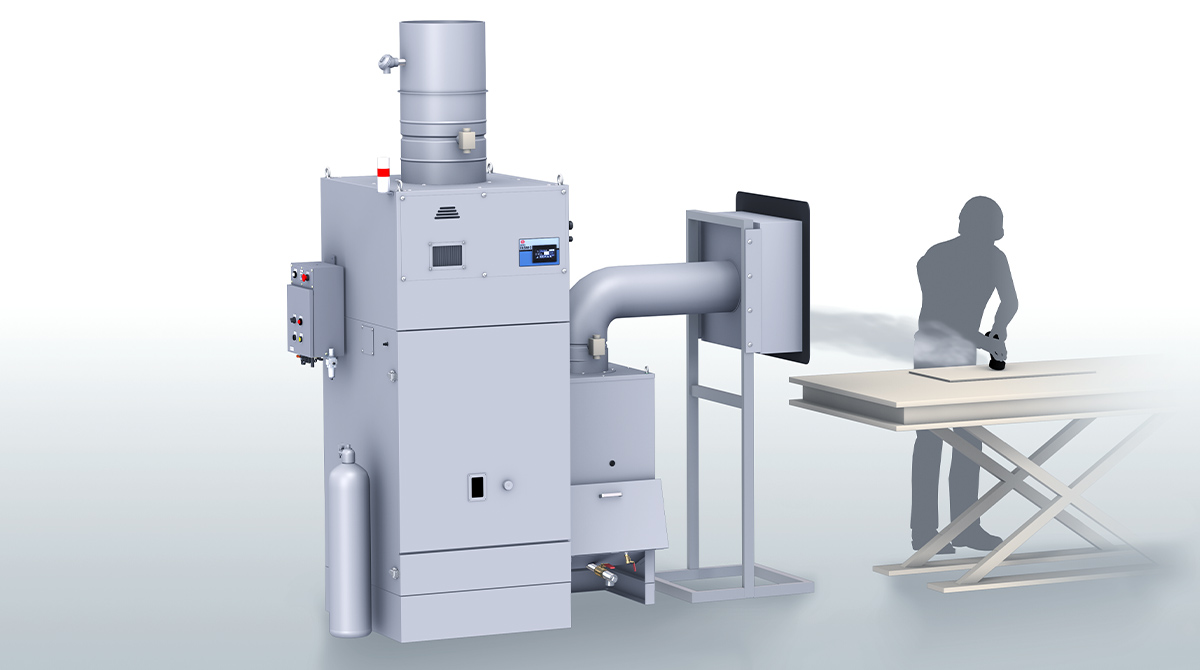

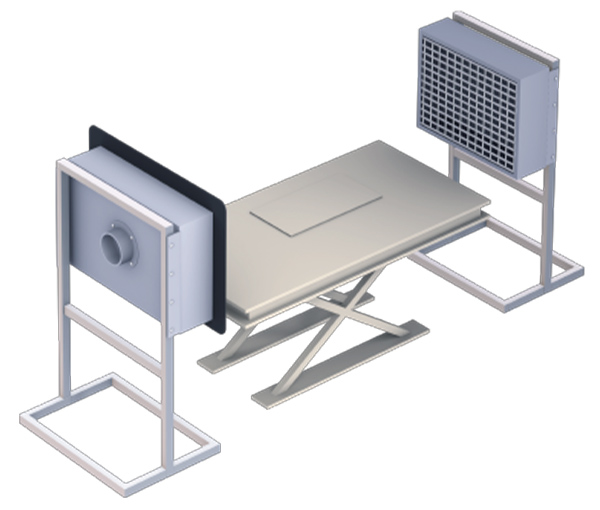

CONCEPT6 - Maintain comfortable working conditionsPush-pull hood

Efficient and comfortable

The push-pull hood collects dust over a wide work area with minimal suction flow. The push hood has an ultra-slim design to easily fit in compact spaces.

▲Push-pull hood

Please consult us for inquiries.

+81-52-581-6896

Available hours: 9:00-12:00 and 13:00-17:00 JST, Monday through Friday

(excluding national and corporate holidays)