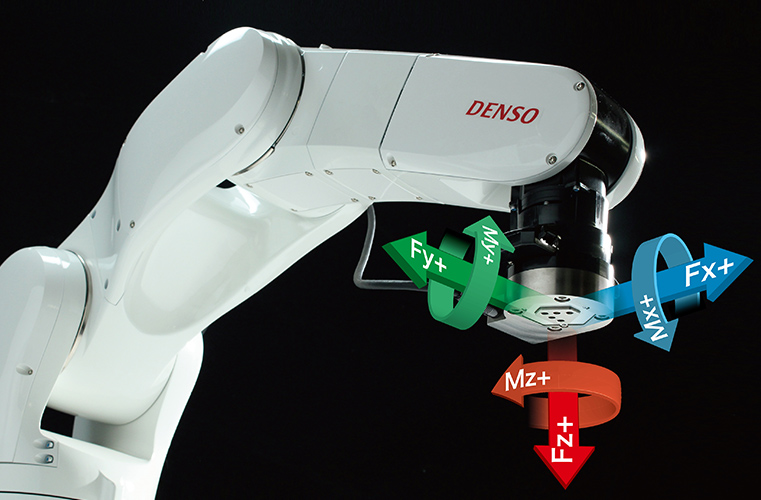

Six-axis force sensor

High-precision [ 2x competing models* ]

High torque [ 2x competing models* ]

High-speed communications [ 5x competing models* ]

*Internal study (May 2019)

Product information

ABOUT

Boost productivity by using robots to replace manual tasks involving complex force control

Our 6-axis force sensor simultaneously detects the load (F) along three axes (XYZ) and the moment (M) around each axis. By attaching a force sensor, you can give a robot a sense of touch and force. The force sensor, like 3D vision sensors and Al, is considered to be a key product for developing intelligent robot technologies.

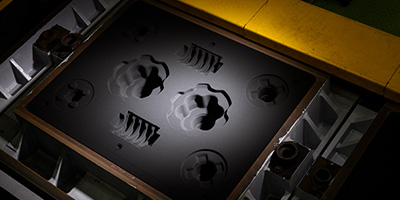

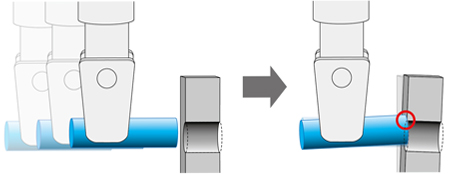

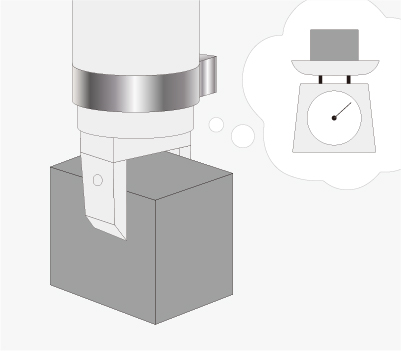

Fitting without a force sensor

With a force sensor installed

Impact is detected and can be corrected immediately

Why install the ZYXer™ force sensor?

BENEFITS

Reduce labor and overcome labor shortages

【 Translate human skills into numerical data 】

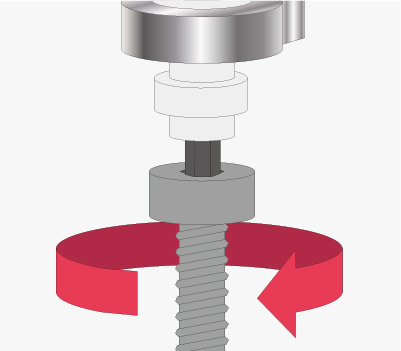

The ZYXer™ force sensor can detect the nuanced force of skilled workers, effectively translating those skills into visual data. This numerical information can then be taught to robots, making it possible to automate not only simple operations, but high-precision tasks as well.

Can be used with high-speed robots

【 Shorten cycle times 】

Our strain gauge force sensor can design much larger rated moments than commonly-used equipment, making it possible to install on robot arms that move at much greater speeds.

Stabilize product quality with high-precision

detection

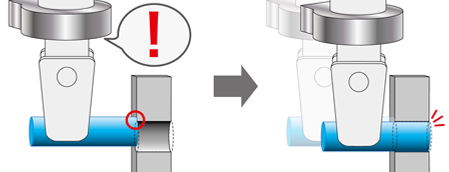

【 Prevent damage to robot hands and workpieces

】

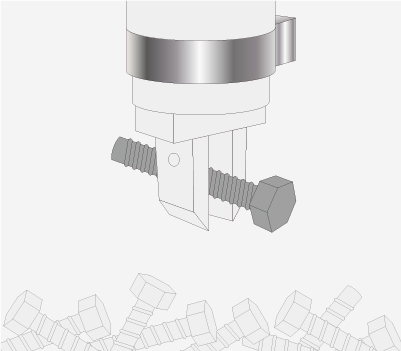

Because the minimum detection load is so small, the ZYXer™ force sensor can detect unexpected contact between robot hands and workpieces, preventing damage. When installed on picking devices, robots can work without damaging even delicate components like screw threads.

Example applications

USE

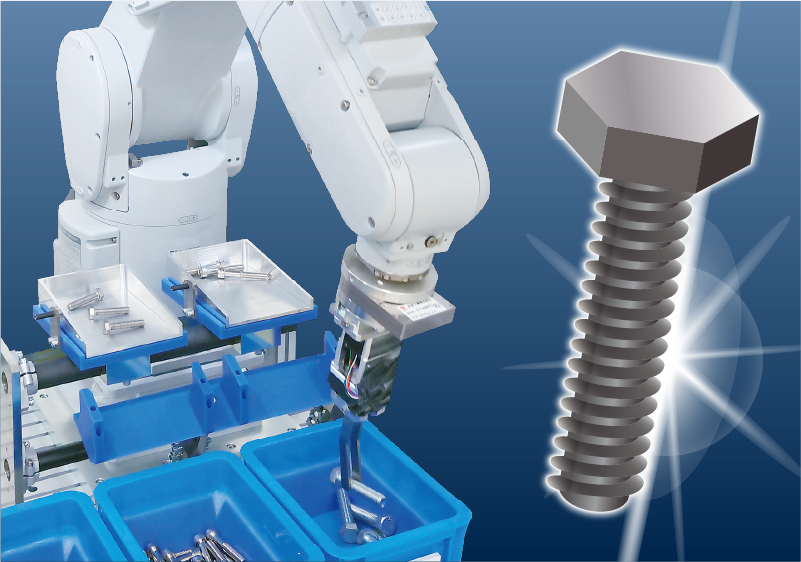

Collaborative robots

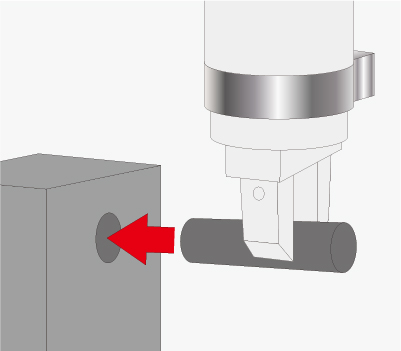

Fitting

Can be used to fit tolerances up to H7

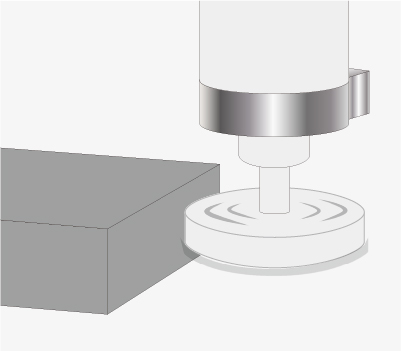

Picking

Work without damaging components or hands

Tightening

Tighten at a specified strength

Measure weight and center of gravity

Just pick up to measure

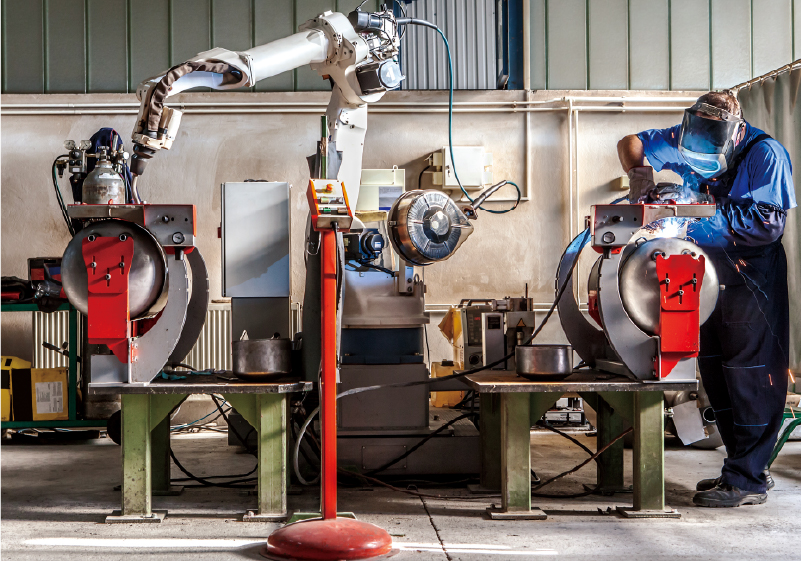

Industrial robots

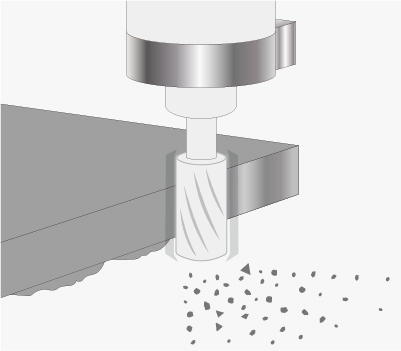

Component grinding

Replicate nuanced force of skilled workers

Deburring

Detect even the tiniest burrs

Installing  on robots makes many things possible

on robots makes many things possible

- Control force and position by sensing interference even from planetary gears. Absorb even slight differences in assembly dimensions.

- Use the ZYXer™’s high precision, high torque, and high communication speed for H7 fittings or deburring.

- Install ZYXer™ to prevent damage during picking operations due to subtleties that vision sensors have difficulty picking up.

- Prevent damage to robot hands and held parts due to irregular motions during operation.

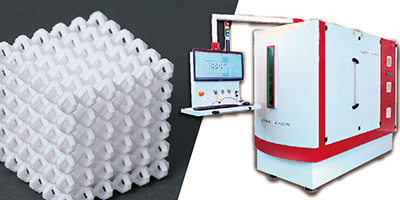

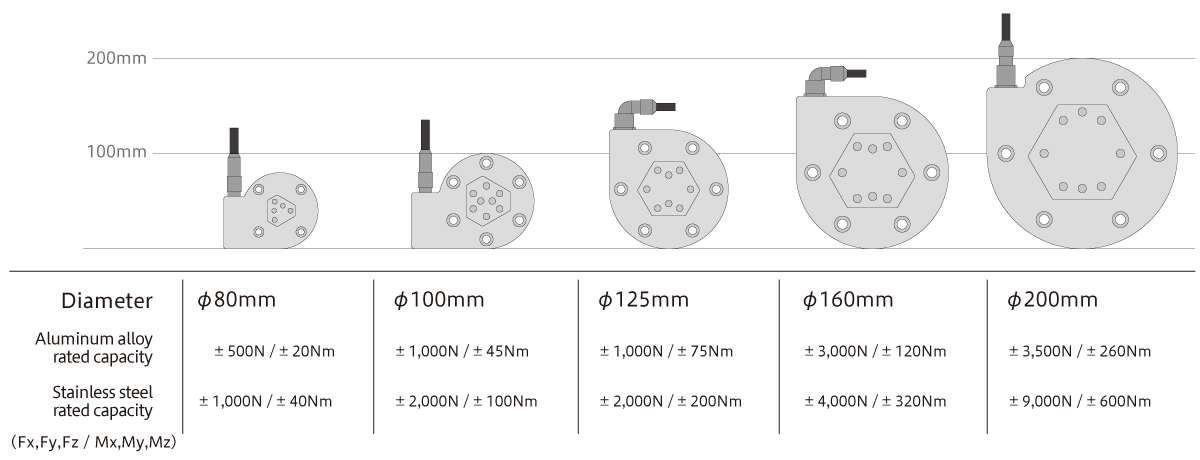

Main models

Can be customized to handle even larger load capacities

We can manufacture force sensors for the robots with larger load capacities that are sold

in Japan.

Ensure reliable grasping and assembly operations by helping human operators with force

detection during transport of diecasts weighing over 1 ton, or when assembling car doors or heavy

equipment tires.

| Sample custom product manufactured by Sinto | ||

|---|---|---|

| Size | Φ 500 × H94 | |

| Rated capacity | Fx,Fy | ± 7,000N |

| Fz | ± 14,000N | |

| Mx,My | ± 3,500Nm | |

| Mz | ± 1,750Nm | |

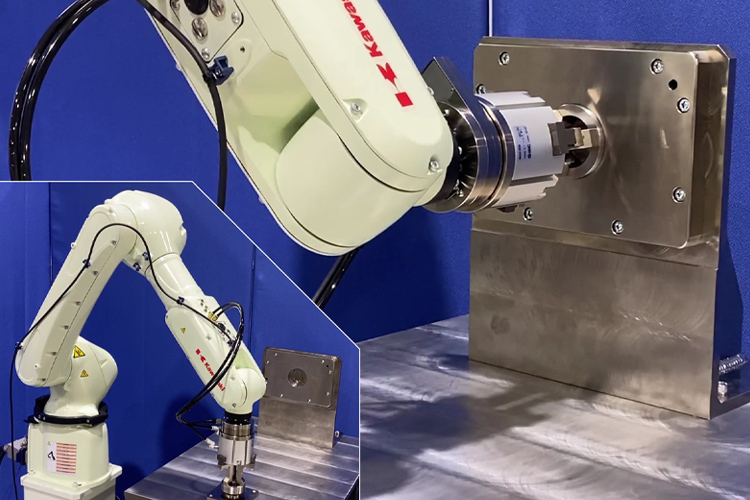

ZYXer in collaboration with robot manufacturers

ZYXer has been adopted by major robot manufacturers like Kawasaki Heavy Industries.

Kawasaki Heavy Industries, Ltd.: Force sensor standard application (fitting system)

Points for installation of ZYXer

- H7 mating is possible without using a vision sensor due to high accuracy and high communication speed.

- Since the moment is high, the work can be transported at high speed compared to regular force sensors.

- Connection to Kawasaki Heavy Industries robots is easy. ※1

Equipment and conditions for use

- Robot model

- RS007L ※2

- Force sensor model

- ZYX080S102

- Fitting tolerance

- H7/g6 (clearance fit)

- Allowable deviation amount (reference value)

- 1mm in X-Y direction, 0.5° in Rx/Ry direction

*1 ZYXer is registered as a K-AddOn product by Kawasaki Heavy Industries, Ltd.

https://kawasakirobotics.com/products-kaddon/strain-gauge-6-axis-force-sensor-zyxer/

*2 The photo shown above is of the above model, but it can also be connected to other Kawasaki robots.

Please consult us for inquiries.

+81-52-581-6896

Available hours: 9:00-12:00 and 13:00-17:00 JST, Monday through Friday

(excluding national and corporate holidays)