Powder Treatment

Better hardening, kneading,

and feeding for better powder

handling operations

Sinto delivers better powder handling operations through comprehensive solutions built on three powder treatment technologies: hardening, kneading, and feeding.

Sinto’s three powder treatment technologies—hardening, kneading, and feeding—add new value to powders in various fields, from chemicals and metals to electronics, natural resources, energy, and materials. The result is materials with higher added value, energy efficiency, and recyclability, contributing to better workability and environmental performance.

Benefits of Sinto powder treatment technologies

Product differentiation and

more added value

Prevent solidification

Prevent dust

Improve solubility

Modify particles

Prevent separation/segregation

Manufacturing process cost reduction and quality improvement

Improve efficient baking and reactions

Increase molding quality and yield

Reduce binder costs

Streamline raw material inflow and handling

Better handling performance

Prevent dust

Reduce bulk

Improve fluidity

Prevent adhesion

Environmental improvement

Prevent dust pollution

Enable sealed transport

Prevent scattering

Waste treatment

Treat incinerated ash and fly ash

Treat sludge

Treat general dust and sludge

Reuse of resources

Recycle valuable dust

Recycle metal chips

Granulate and reuse reaction byproducts

Technologies/products

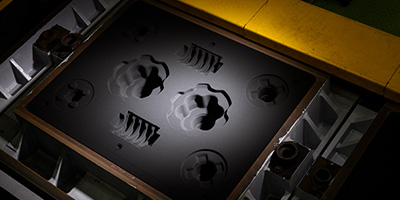

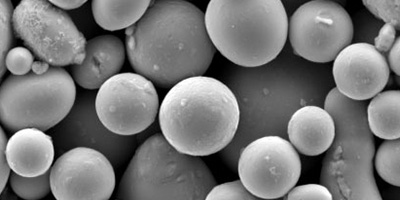

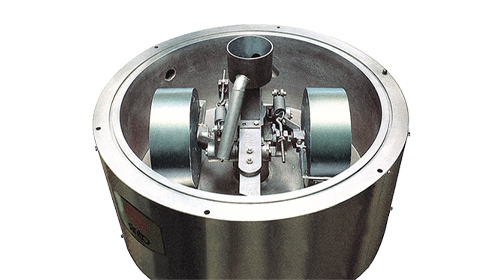

Granulation

Harden powder into granules to add functionality and value in a single step

Hardening powder into granules can add both functionality and value.

Sinto’s powder technologies help customers make more efficient use of energy, reduce volume, improve the work environment, reuse resources, and more.

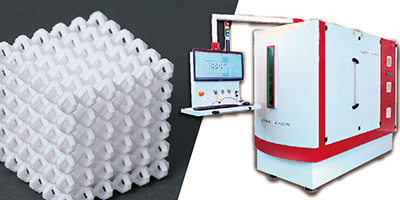

Hardening

Kneading

Improve workability while lowering costs

Kneading makes it possible to reliably perform several tasks at once, including mixing, crushing, pounding, and squeezing.

The three operations of kneading, smearing, and spatulating result in superior kneading force, helping to increase workability while lowering costs.

Mixing/kneading

Pneumatic transport

Inline transport contributes to an improved plant environment

Pneumatic transport is used widely in powder transport operations.

Sinto’s pneumatic transport technology keeps powder “alive” as it moves, preventing stagnation, clogging, adhesion, and other problems in the piping for reliable operations around the clock. Our extensive track record has resulted in reliable pneumatic transport options that help improve conditions in our customers’ plants.

Transport

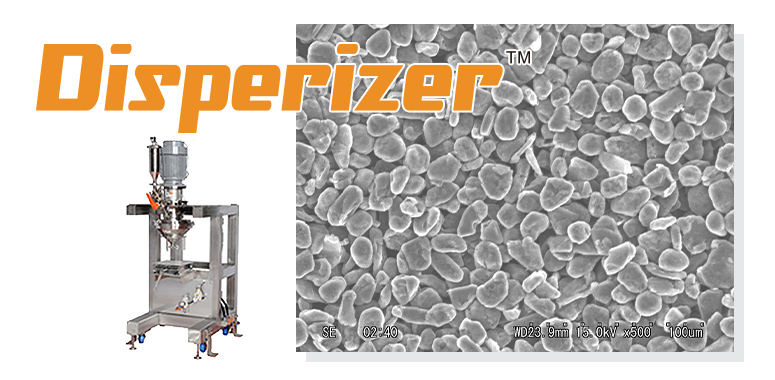

Dispersal

For uniform loosening of flock

Evenly loosen concentrated, clumped powder

Simple dispersal operations improve powder quality while effectively guarding against contaminants.

Loosen

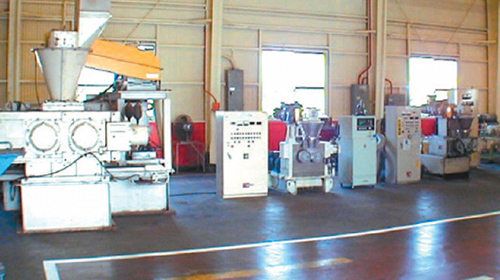

Powder solutions

Sinto offers comprehensive powder treatment solutions

Our granulators, pneumatic transporters, and kneaders/mixers work as standalone installations or as part of fully-engineered systems backed by our powder treatment expertise, complete with dust collectors and other environmental equipment, increasing the added value of our customers’ powder.

We can solve your

powder issues

Please consult us for inquiries.

+81-52-581-6896

Available hours: 9:00-12:00 and 13:00-17:00 JST, Monday through Friday

(excluding national and corporate holidays)