Electronic core materials

Magnetic metal powder

Get even finer alloy powders,

down to the micron

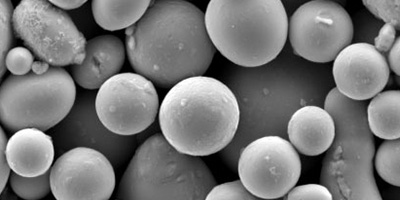

Sinto’s magnetic metal powders

Magnetic metal powder is primarily used as a core material in electronic components found in communications devices (including smartphones and those installed in automobiles) and controllers.

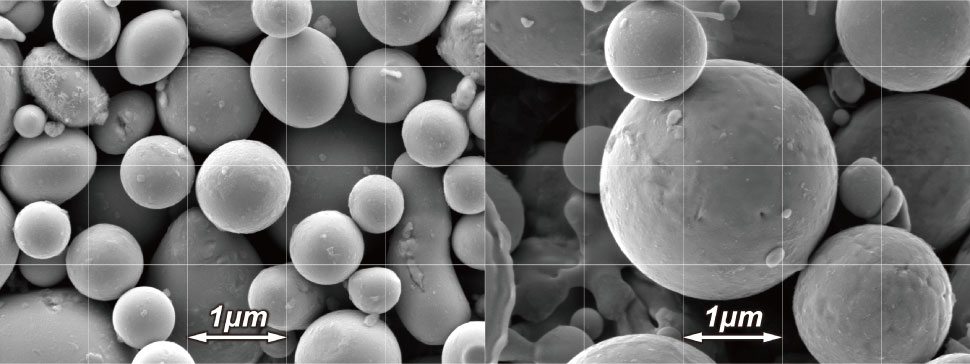

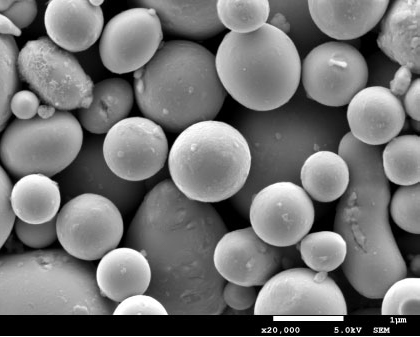

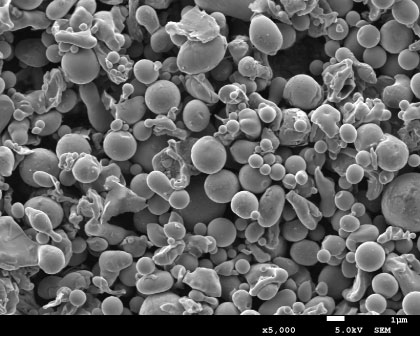

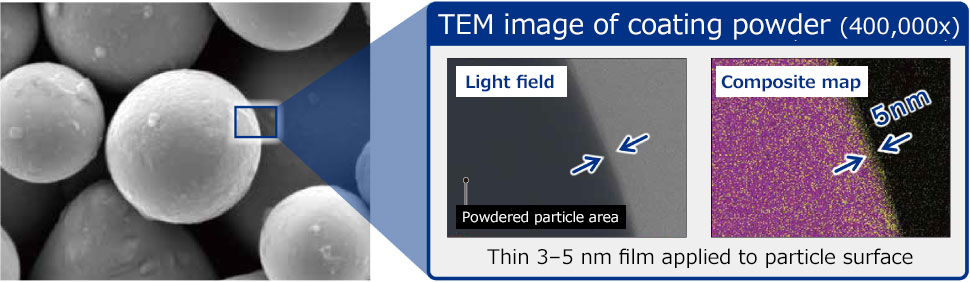

Designed using our surface treatment blasting media (steel shot) technologies developed over decades, our magnetic powders are crafted to achieve minute particle sizes and high reliability. As a result, we are able to mass-produce magnetic metal powders with an average particle diameter of just two microns.

Only possible with micron-level magnetic powders

Lamination

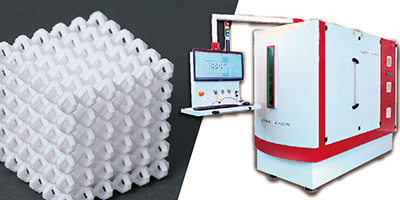

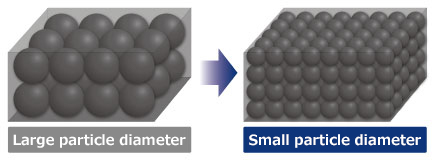

The use of ultrafine powder helps create smaller, lower-profile electronic components

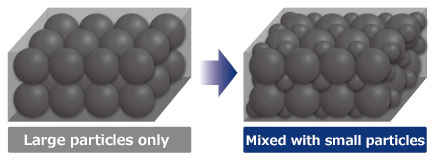

High-density filling

Filling in the spaces between granules creates a high-density fill with better magnetic performance for smaller electronic components.

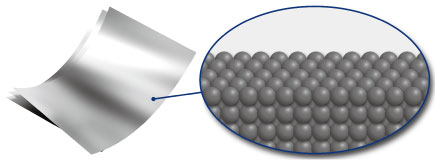

Thinner sheets

Finer granules keep surface unevenness to a minimum for thinner sheets.

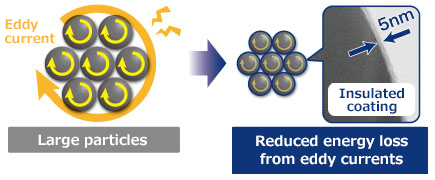

Higher-frequency applications

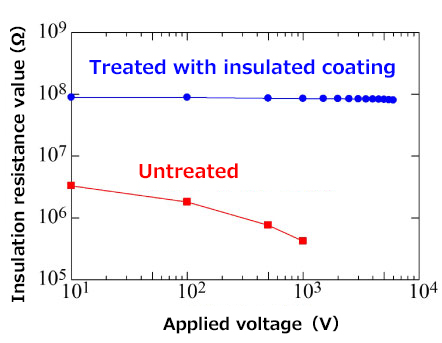

Sinto’s unique amorphous structure delivers low-loss, low-anistropic, low-resistance performance. The addition of an insulated coating can reduce loss even further.

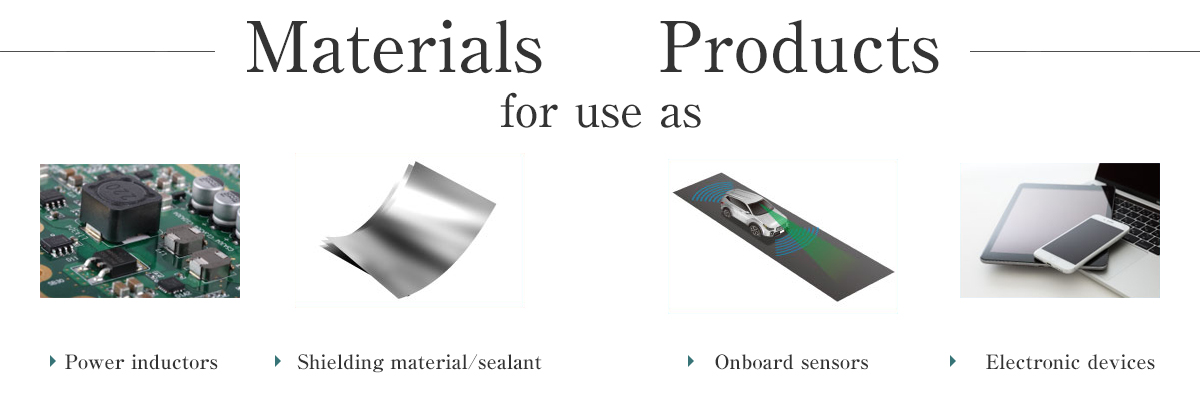

Applications

Note: Applications provided as examples only. Designed to increase the reliability and performance of electronic components. Please inquire for details.

Product lineup

Magnetic metal glass powder (amorphous)

SAP series

- Ultrafine metal powders created using our proprietary high-pressure water atomizing technique

- Smooth surface characteristics for high-density filling and better resin mixability

- Patented composition technology creates some of the lowest-loss materials in the industry

Product features

| Item no. | Particle size distribution [μm] | Specific surface area [㎡/g] | Oxygen concentration [wt%] | Saturation magnetization [emu/g] | ||

|---|---|---|---|---|---|---|

| D10 | D50 | D90 | ||||

| SAP-2D (C) | 1.1 | 2.3 | 4.2 | 0.7 | 0.6 (prior to coating) | 150 |

Note: We can also produce particles of other sizes (diameters of 10μm or less)

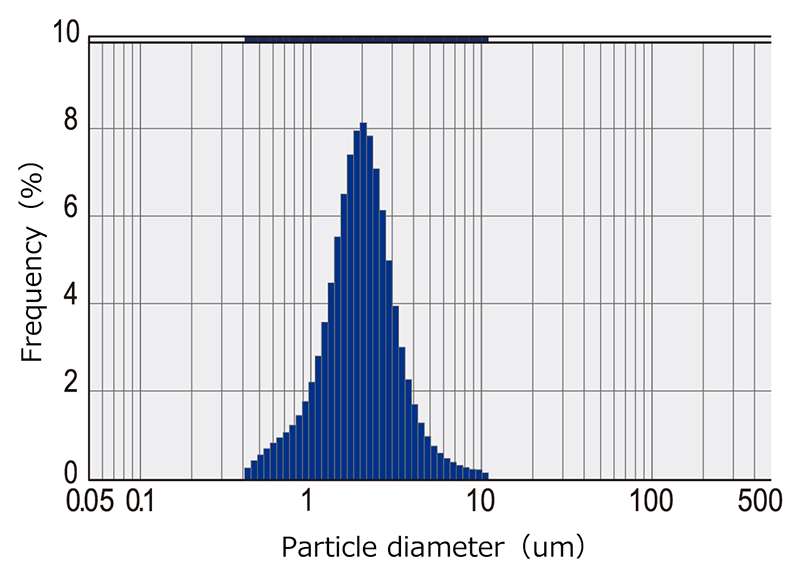

Particle size distribution

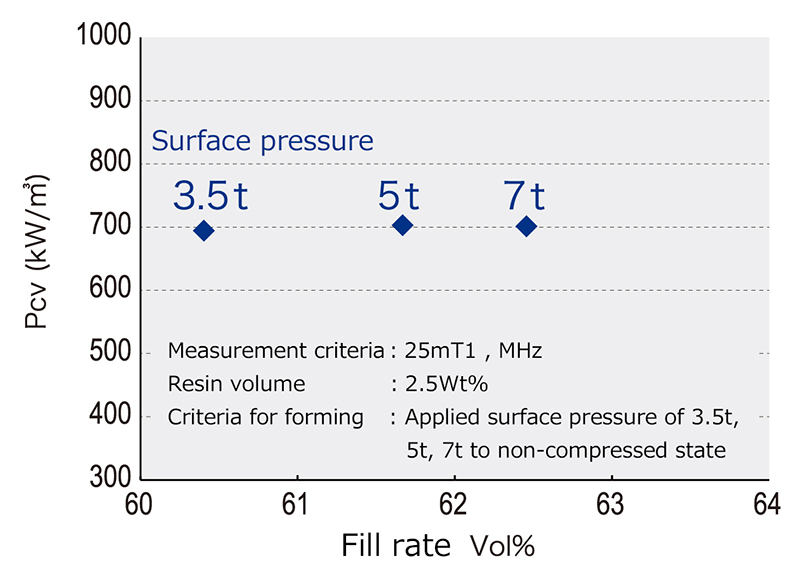

Magnetic characteristics

Example using 2 μm particles. Particle size distribution range can also be customized. Please contact us for details.

Magnetic metal powder (FeSiCr)

FSC series

- Ultrafine metal powders created using our proprietary high-pressure water atomizing technique

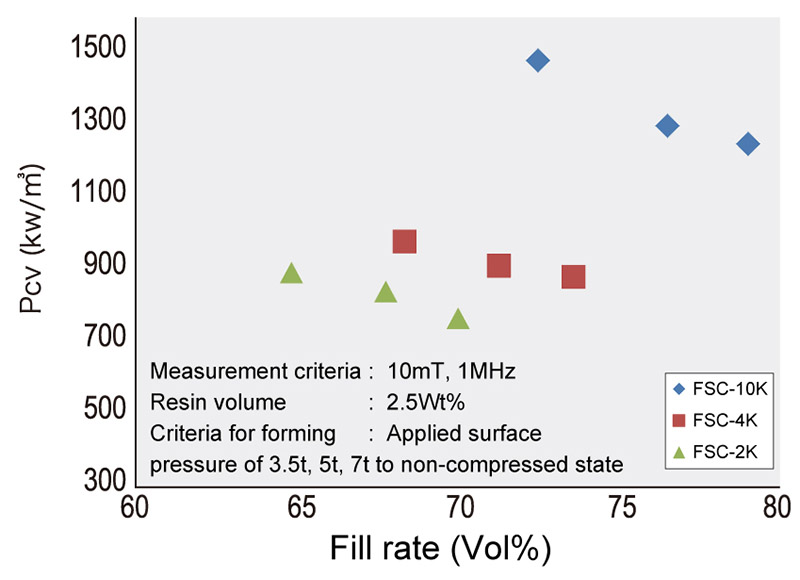

- Can be combined with larger particles for high-density filling applications

Product features

| Item no. | Particle size distribution [μm] | Specific surface area [㎡/g] | Oxygen concentration [wt%] | Saturation magnetization [emu/g] | ||

|---|---|---|---|---|---|---|

| D10 | D50 | D90 | ||||

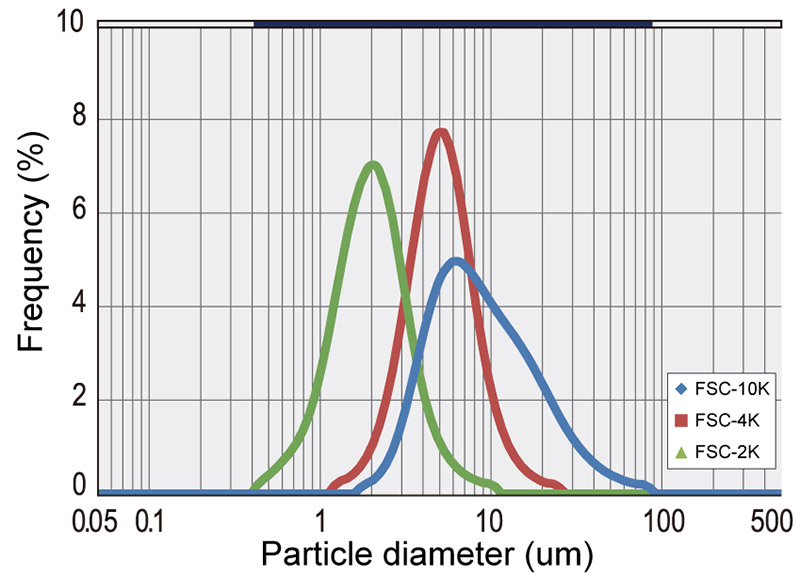

| FSC-2K (C) | 1.2 | 2.1 | 3.7 | 1.0 | 0.6 | 180 |

※Note: We can also produce particles of other sizes (diameters of 10μm or less)

Particle size distribution

Magnetic characteristics

Example using 2 μm particles. Particle size distribution range can also be customized. Please contact us for details.

Insulated coating

Insulation performance

Insulation performance

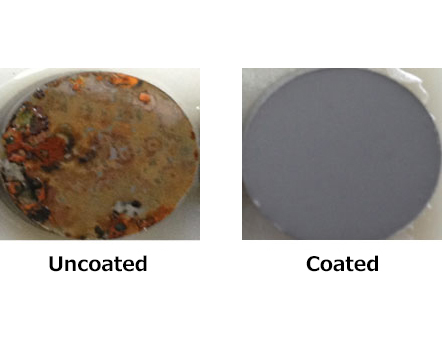

Salt spray durability test (zero rust after 96 hours)

Please consult us for inquiries.

+81-52-581-6896

Available hours: 9:00-12:00 and 13:00-17:00 JST, Monday through Friday

(excluding national and corporate holidays)