V-Process molding

Perfect for large and midsized castings,

Sinto’s V-Process technology delivers beautifully refined surfaces,

and it can also be used for prototype casting.

Since developing the world’s first V-Process automated molding machine in 1972, Sinto has continued to build our know-how in the field, installing over 200 V-Process lines in twenty countries.

We use our extensive expertise and skills, along with equipment that makes full use of our proprietary technologies, to optimally engineer our customers’ V-Process plants.

V-Process equipment

Produces beautiful casting surfaces with superior dimensional accuracy for large or midsized castings

Uses binder-free dry sand to reduce waste and hazardous gas emissions for more eco-friendly casting production

Features

High-quality, low-cost casting

Beautiful casting surfaces and high dimensional accuracy

Greatly reduces need for finishing processes, resulting in lower machining costs

High production efficiency

Easier sand filling and shake-out than with chemically bonded processes

Realization of a production line for large and midsized castings based on Sinto’s engineering expertise

Environmentally friendly

The use of binder-free dry sand reduces waste and hazardous gas emissions, for worker- and environment-friendly casting production

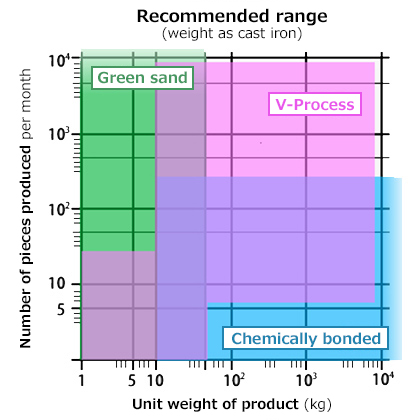

Applicable range

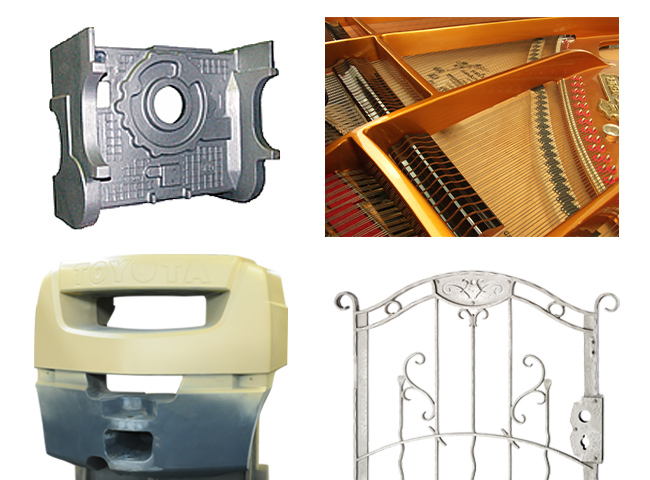

The V-Process can be applied to a wide range of production volumes and product weights, with a focus on creating beautiful casting surfaces and detailed patterning on aesthetic aluminum parts and similar products. It is commonly used for larger products that cannot be produced using green sand molding.

Applicable weight per unit: Up to 8 tons

Production volume: Up to 8,000 pieces/month

When choosing a molding process, it is also important to consider product shape and purpose.

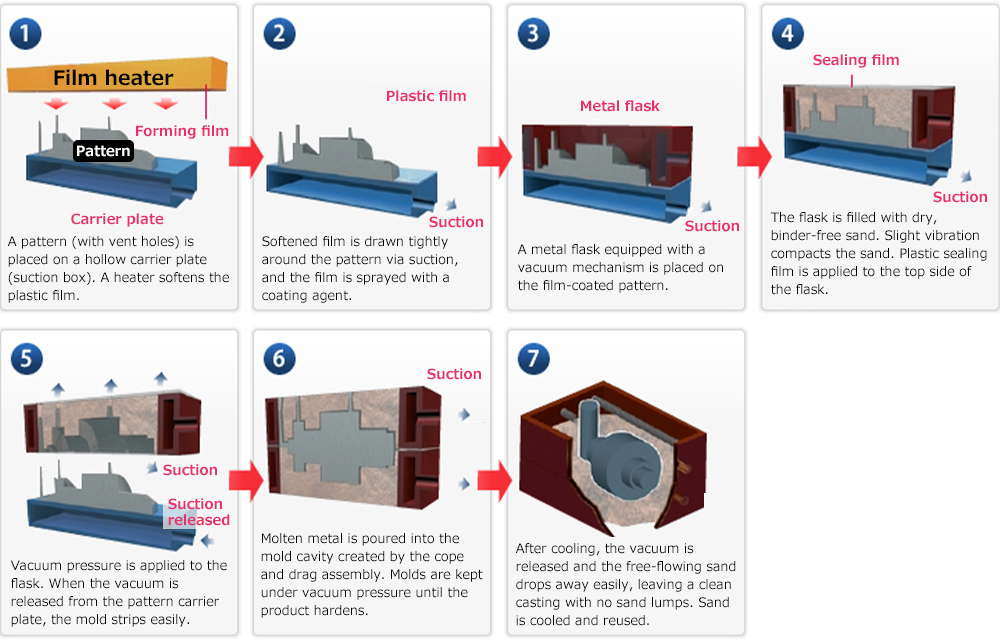

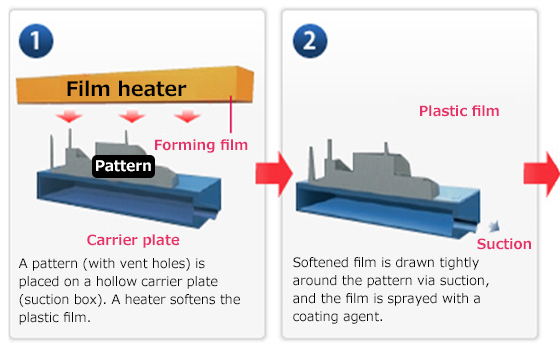

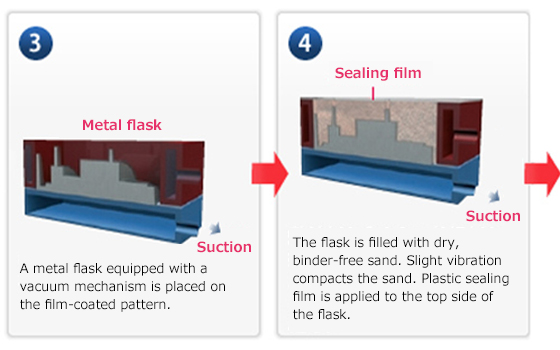

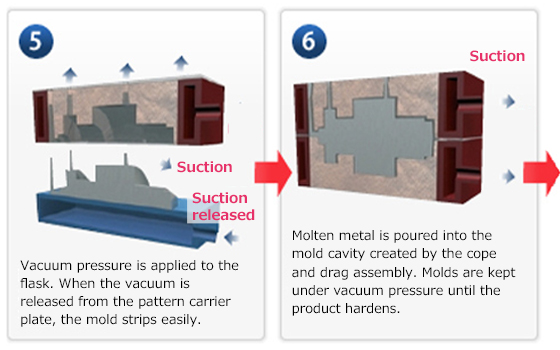

V-Process stages

Plant usage examples

Beautiful surfaces with high dimensional accuracy

Piano frame V-Process system

Flask inner dimensions: 1900 x 1650 x 250/250 mm

Molding capacity: 15 molds/hour

Automated line capable of handling large molds for products up to 3.3 tons

Product: Counterweight

Product weight: 2,000–3,300 kg

Flask inner dimensions: 2000 x 2000 x 550/1200 mm

Molding speed: 10 min/complete mold (6 molds/hour)

Railcar frame

Product: Railcar component

Product weight: 300–600 kg (multiple products per mold)

Flask inner dimensions: 3000 x 1600 x 500/500 mm

Molding speed: 3 min/complete mold (20 molds/hour)

Semi-automated, high-mix line with low initial costs

Motor frame

Products: Manholes, automotive parts, machine parts

Product weight: 200–1,000 kg

Flask inner dimensions: 2000 x 1900 x 270/430 mm

Molding capacity: 15 min/complete mold (4 molds/hour)

Please consult us for inquiries.

+81-52-581-6896

Available hours: 9:00-12:00 and 13:00-17:00 JST, Monday through Friday

(excluding national and corporate holidays)