Green sand molding

- Casting production that is worker- and

environment-friendly, aiming for net-shaping,

thinning/weight reduction, and zero defects

Sinto has developed unique, world-renowned technologies such as V-Process, SEIATSU, and aeration, and we have developed a rich product lineup backed by extensive experience and expertise. We provide our customers with the right equipment and comprehensive solutions for better casting production. Aiming for net shape, our superior molding technologies make it possible to produce high-precision molds that achieve near-net shape and thinning/weight reduction.

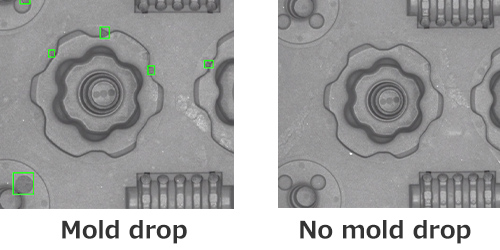

More recently, we’ve also been aiming for zero defects, employing IT solutions to prevent quality problems at every step. This gives us the numerical data we need to visually track the status of each process and keep quality variations to a minimum.

Net shaping and thinning/weight reduction through better casting production

Providing thinner, lighter products

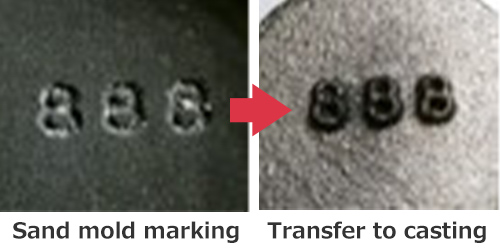

Mold production with highly precise mold dimensions, making thinner products possible

Sinto delivers superior molding performance—even with thin, complex shapes.

Effects

- Lighter-weight castings

Usage example

Motor cooling fin

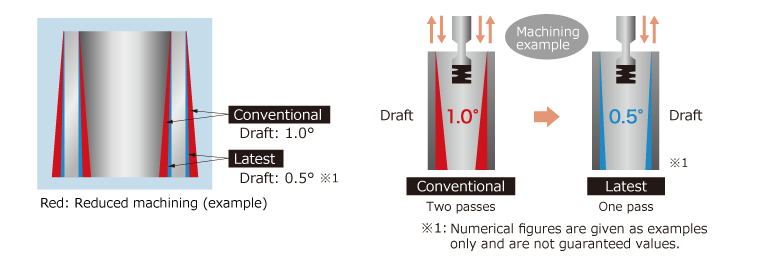

Benefits of near-net shape

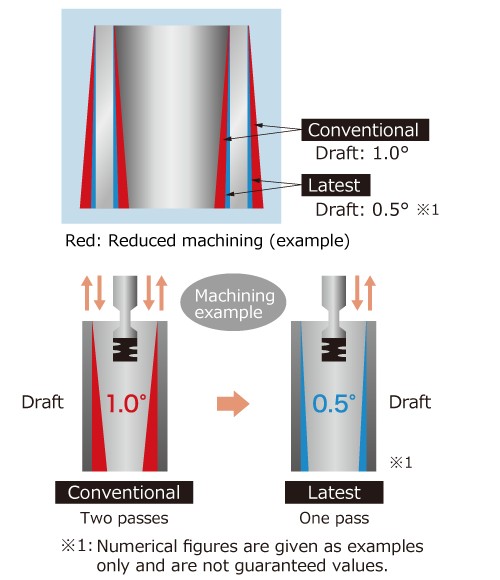

Reduced draft

Reduce casting material weight and the need for machining in subsequent processes

Effects

- Less cutting in following processes

Less time, lower cutter costs - Less energy used for melting

Our Good Casting System™ uses net shaping

and thinning/weight reduction to achieve better casting production

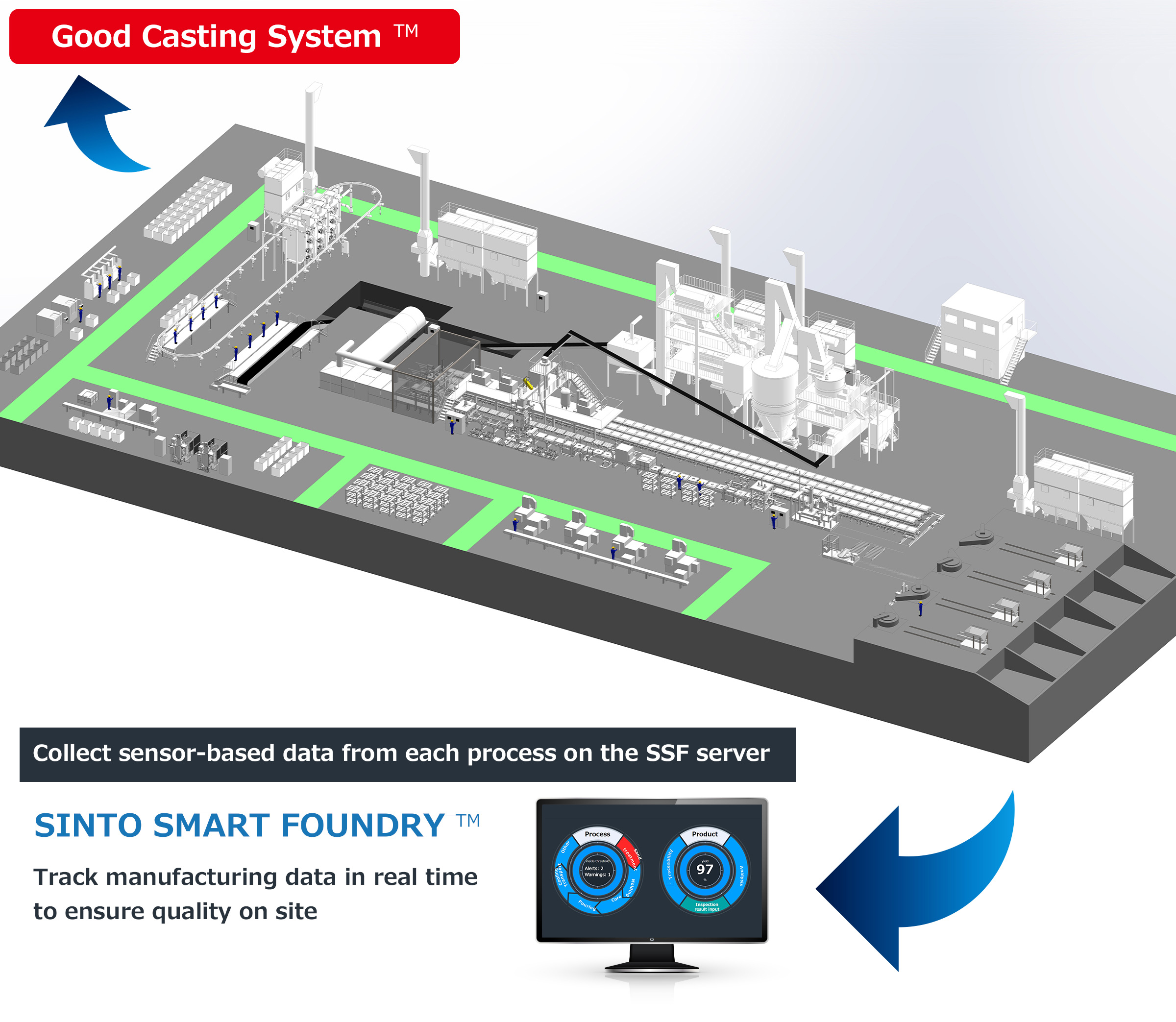

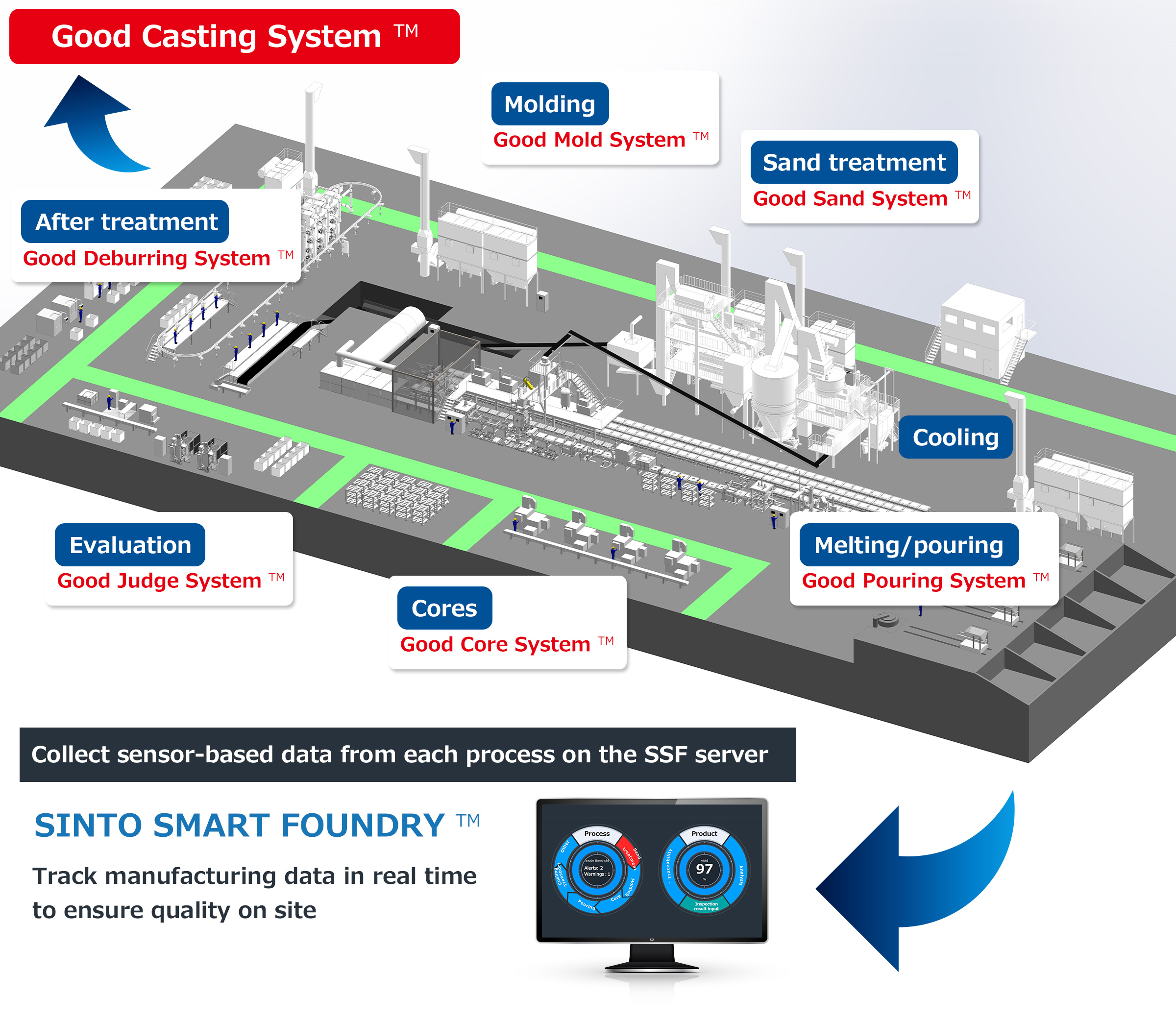

SINTO SMART FOUNDRY

Proposals to achieve zero quality defects for better casting production

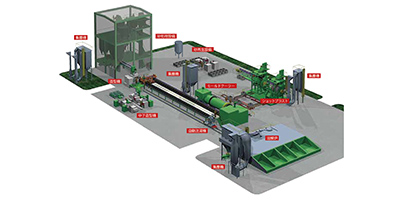

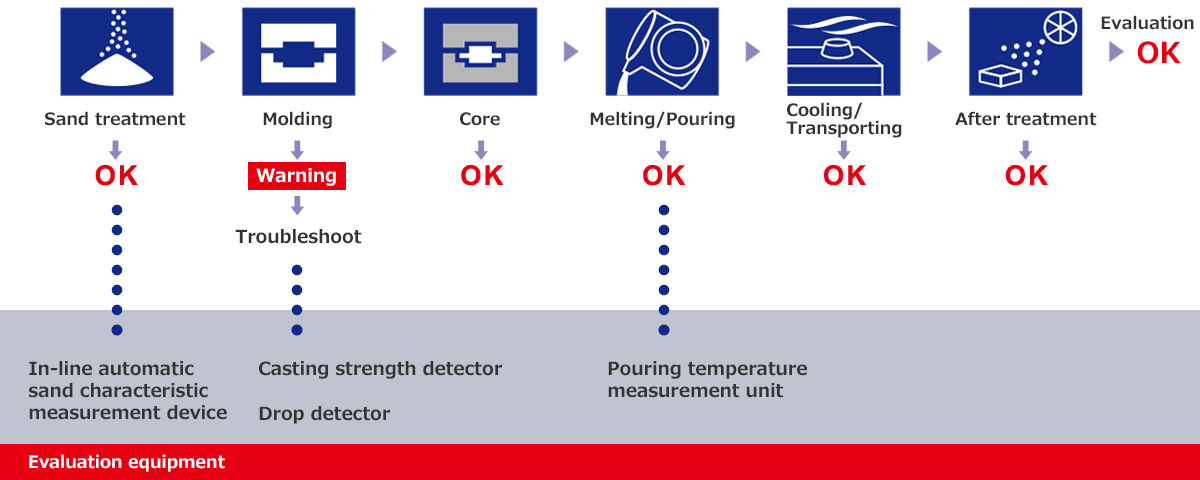

From sand treatment to molding, cores, pouring, cooling, and after treatment, Sinto evaluation sensors collect manufacturing data from every stage of the casting process for advanced digitization, collection, and visualization. Understand the situation in real time and analyze the data to identify the root cause of defects.

Benefits

(1)Minimize variation for more reliable casting quality

(2)Fully-automated processes keep defects from moving on to the next process, improving casting quality

Evaluation equipment

Evaluation equipment monitors each process.(3)Visually track numerical quality data

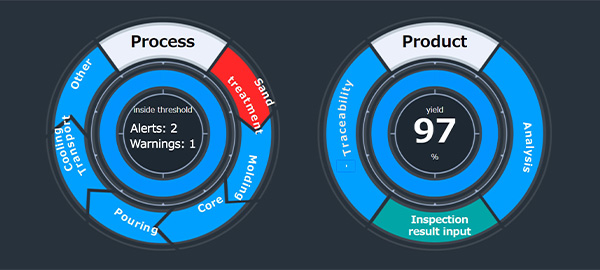

SSF main menu

Centralized display by flask of all factors impacting quality

Sand treatment systems

(Recovery, screening, cooling/storing, mixing, feeding)

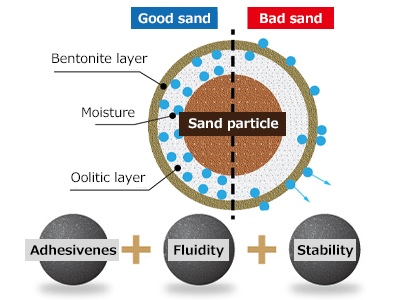

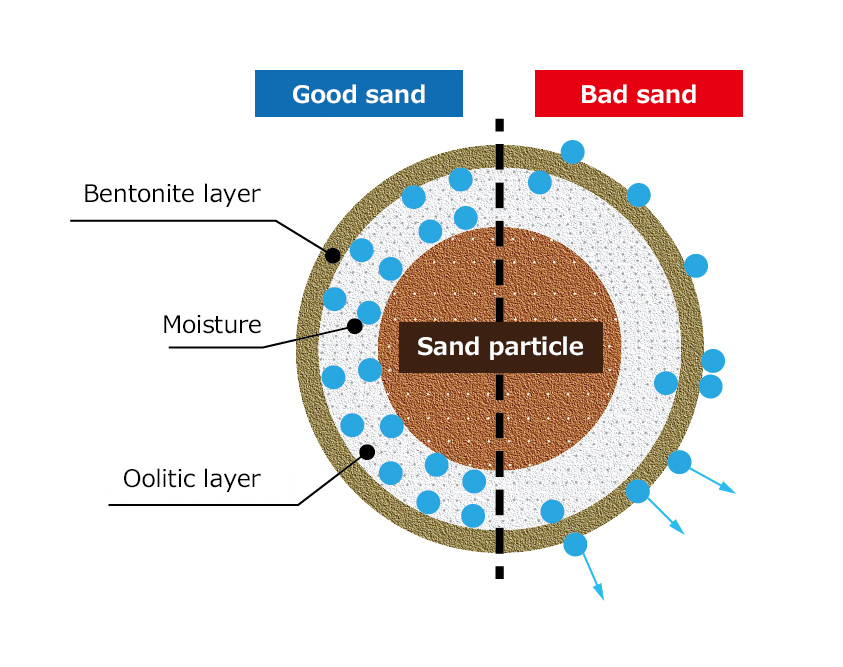

Better casting production starts with better sand

There are three criteria for quality green sand (adhesiveness, fluidity, stability), so its micro-properties must be properly managed to ensure that only particles that meet all three are being supplied.

Taken to the extreme, this means controlling the properties of every grain of sand. If you can see the sand particles, you know how the casting is going to turn out. Sinto sand treatment supports the production of better castings.

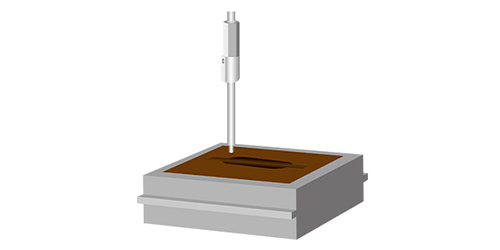

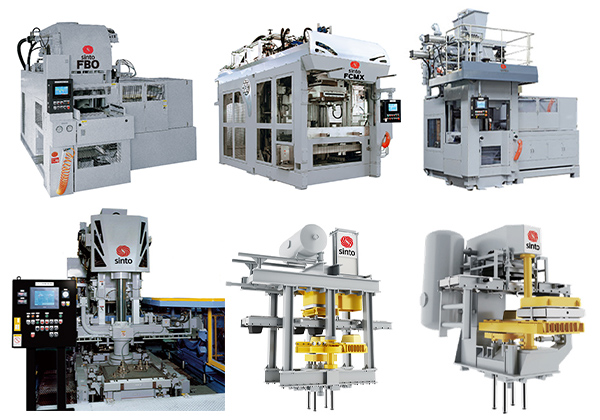

Green sand molding systems

For superior-quality molds

Sinto’s extensive lineup of molding systems is built on our proprietary core technologies. We can provide the ideal molding machine to create superior-quality molds to match the product size, shape, and production criteria you need.

We propose molding systems that include evaluation devices, allowing you to check the quality of your molds for better casting production.

Core molding systems

Core molding systems designed to create a low-odor, operator-friendly work environment

Cores are at the heart of casting. At Sinto, our systems don’t just produce high-quality cores, they also minimize odors so they’re better for workers and the environment. Our total core systems provide automated core operations, labor-saving engineering, core sand reclamation systems, and more for cold box molding, inorganic cores, and shell molds.

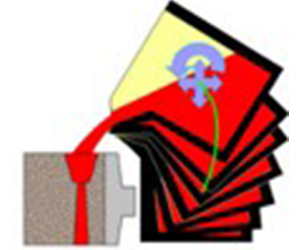

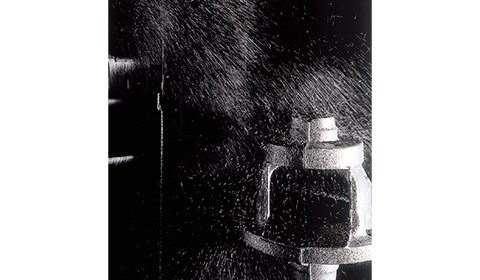

Pouring systems

Precision pouring systems that keep pouring-related defects to a minimum

From inflow to pouring, we ensure the safety and reliable operation of our customers’ casting production. Our cutting-edge inflow, transfer, and pouring systems provide automated operations, labor savings, an improved work environment, increased quality, and lower costs.

Cooling systems

Optimized product cooling for higher productivity and better quality

Sinto offers optimized product cooling systems that boost productivity and increase quality by adjusting cooling time to match the needs of every product.

After treatment equipment

For high-quality, efficient finishing of castings

Our after treatment lineup includes equipment that crushes molds and separates products from sand before cooling them, as well as shot blasting for sand removal.

We offer products that are tailored to each customer’s product size and production requirements.

IoT solutions

Using IT in pursuit of zero defects

Sinto uses IT to create systems that reduce quality defects at each casting production process through sensing of manufacturing conditions, digitization, data collection, and more.

We also offer a variety of IoT-powered preventative maintenance systems to keep equipment running safely and reliably.

Environmental solutions

Worker- and environment-friendly casting production

We contribute to the evolution of casting production that is worker- and environment-friendly. We work to achieve a clean, comfortable factory environment that is easy to work in.

Engineering

Total engineering solutions for better casting production

Sinto has developed unique, world-renowned technologies such as V-Process, SEIATSU, and aeration, and we have developed a rich product lineup backed by extensive experience and expertise. We provide our customers with the right equipment and comprehensive solutions for better casting production.

Please consult us for inquiries.

+81-52-581-6896

Available hours: 9:00-12:00 and 13:00-17:00 JST, Monday through Friday

(excluding national and corporate holidays)