Chemically bonded sand

Delivering better casting production

- Alleviates labor shortages

- Achieves reliable product quality

- Creates a clean, comfortable work environment

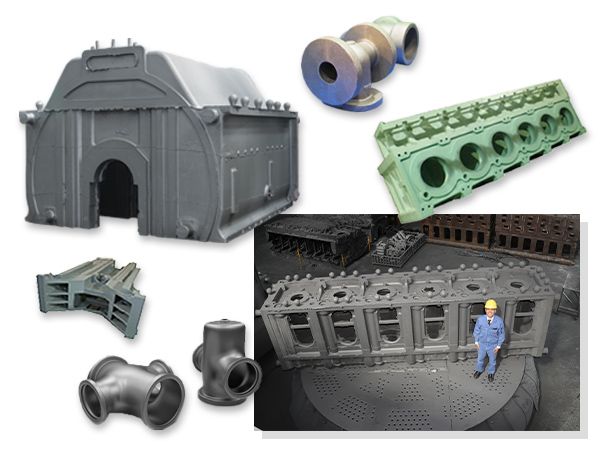

For castings of any size

- We offer chemically bonded sand equipment that maintains exceptional quality, eliminating the need for reworking.

- Automated, labor-saving solutions reduce physical work and other forms of worker strain to help alleviate labor shortages.

- Spilled sand and scattered dust are kept to a minimum for a cleaner, more comfortable work environment.

Omega chemically bonded sand systems offer automated, labor-saving solutions, contributing to the alleviation of labor shortages and reduced labor costs

Benefits

- Reduction of heavy labor, labor savings, and standardization of skilled work

- With flaskless machines, elimination of the space and effort needed to maintain flasks

- Lightweight, low-noise equipment for a more comfortable work environment

We offer the right product for every need and every budget

Starting with easily-managed processes, we help customers achieve labor savings through improved work efficiency, as well as automation.

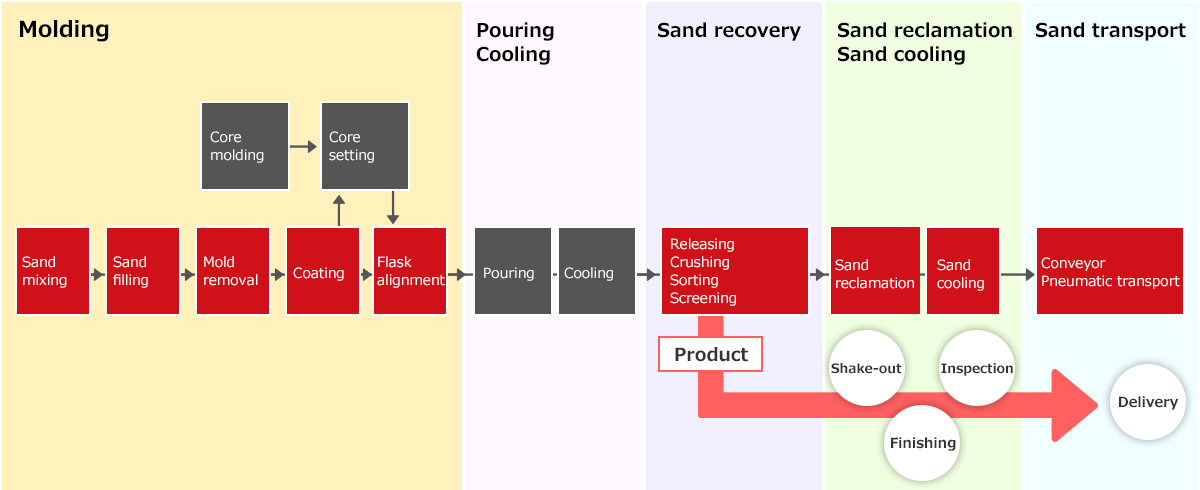

Molding processes

Chemically bonded sand molding systems

(mixing, filling, inverted mold removal, coating, flask alignment)

For high-precision, high-quality casting production

In pursuit of better casting production, we are aiming to achieve casting production that eliminates rework.

Our lineup of molding equipment enables high-precision, high-quality casting production, and with flaskless production, it is possible to produce molds that are customized to products without metal flask sizing limitations. Sinto also provides solutions for standardization and labor savings to help alleviate labor shortages.

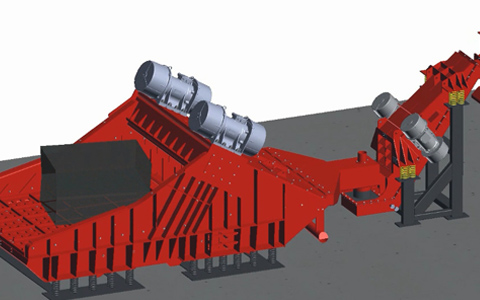

Chemically bonded sand recovery systems

(releasing, crushing, sorting, screening)

Reduced noise for a better work environment

Cleanly separate casting products from casting sand and foreign material, recovering usable sand. Our recovery systems allow for small pits and lower initial costs.

Choose flaskless equipment for lower weight and noise, resulting in a friendlier work environment.

Chemically bonded sand reclamation/sand cooling systems

High sand reclamation rates for reduced waste output

Reclaimed sand plays a critical role in casting quality, and the reclamation process must manage multiple factors that directly impact it, such as sand quality, granularity, and powder volume. At Sinto, we provide the optimized sand reclamation systems customers want, tailored to their various production processes. Our high-yield sand reclamation systems reduce waste output volume as well.

Chemically bonded sand transport systems

Prevent spilled sand and scattered dust for a cleaner, friendlier foundry plant environment

Our reliable sand transport systems are built on the pneumatic transport technologies we have developed in the powder processing sector over many years. Our sealed sand transport lines prevent spilled sand and scattered dust, contributing to a cleaner, friendlier work environment.

After treatment equipment

We offer the optimal shot blasting equipment for every product size and weight

Sinto offers shot blasting for shake-out and deburring, optimized to a variety of conditions including production type, size, and weight. We also provide high-quality blasting abrasives to ensure that customers are able to maximize the performance of their shot blasting equipment.

Please consult us for inquiries.

+81-52-581-6896

Available hours: 9:00-12:00 and 13:00-17:00 JST, Monday through Friday

(excluding national and corporate holidays)