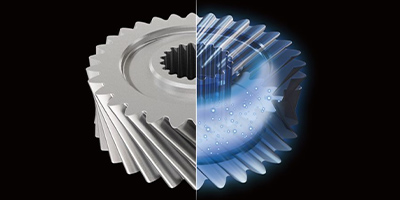

Topics for surface treatment

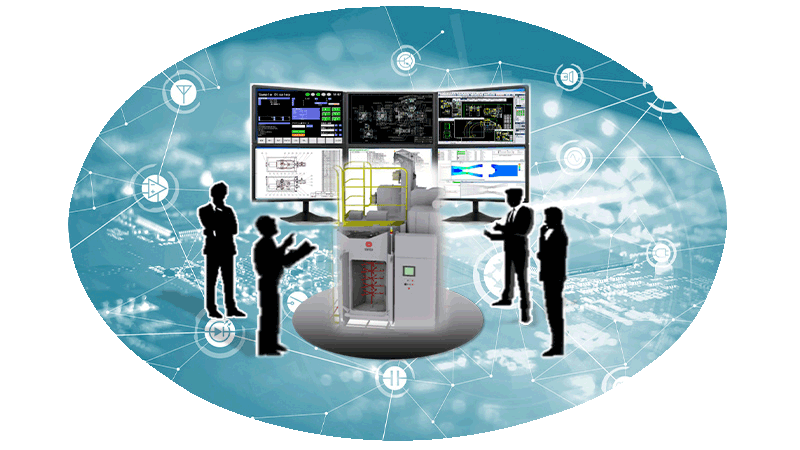

IoT-powered manufacturing

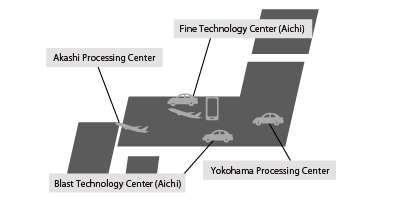

Sinto Virtual Technology Centers

The Blast Technology Center (BTC), our key surface treatment center in Aichi Prefecture, is linked with the Yokohama and Akashi Processing Centers through an IoT-powered network that allows engineers at the Blast Technology Center to monitor and track equipment operational status at these processing centers remotely.

By linking verification testing, evaluations, specification meetings, and trial runs, Sinto is able to provide virtual-reality surface treatment solutions.

Ideal processing conditions

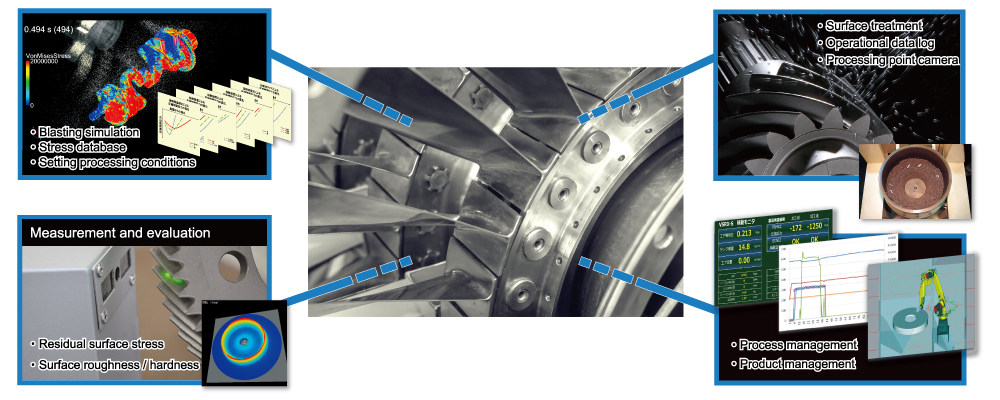

Processing simulations

We provide the surfacing solutions our customers need, backed by processing analyses and our collected data.

One-stop solutions

Processing condition simulations were once only available at our Technology Center, but our processing centers can now handle everything from simulations to processing work, measurements, and evaluations.

Take advantage of the convenient, rapid surfacing solutions Sinto can provide.

Sustainable manufacturing

Learn more about Sinto’s initiatives to support eco-friendly manufacturing for a low-carbon society.

CO² reduction: 56%

Eco-ship and Eco-rail certified by the Japan Ministry of Land, Infrastructure and Transport (MLIT)

The Japanese government is promoting a modal shift strategy that aims to curb CO² emissions and energy consumption in corporate logistics by encouraging companies to move from trucking to maritime and rail transport.

At Sinto, we’ve been able to greatly reduce CO² emissions by transporting the blasting abrasives we produce at Osaki Works (in Toyokawa, Aichi) to the Kyushu area via ferry from Osaka Nanko Port to Shin Moji Port instead of long-distance trucking.

We’re also working to gradually expand our rail transport, which is currently in operation in Hokkaido, to include the Tohoku and Joshin-etsu regions as well.

In recognition of our efforts, we’ve received certifications from the Eco-ship Modal Shift Project Executive Committee and the Eco-Rail Mark Management and Certification Committee established under MLIT.

Recovery rate:

Around 30%

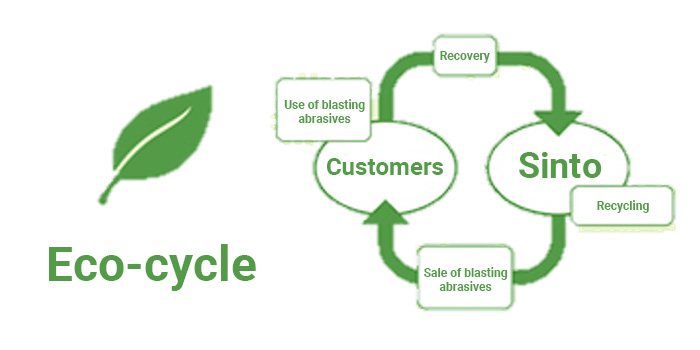

How our recovery and recycling system for used blasting abrasives works

Sinto is the only manufacturer with its own recovery and recycling system for the blasting abrasives used by our customers as well as the dust they collect. These practices promote a circular economy, not only reducing the amount of waste produced but also helping our customers reduce costs.

- Recovered/recycled blasting abrasives

- Steel shot, grit, zinc shot, stainless steel shot

Harmful compounds: Zero

Eco-friendly compounds

Sinto compounds lead the industry in environmental responsibility, as we’ve been offering nothing but eco-friendly products since 2000. We support green production activities by eliminating all specified substances under Japan’s PRTR Law as well as all toxicants listed under the Water Pollution Prevention Act.

About compoundsPlease consult us for inquiries.

+81-52-581-6896

Available hours: 9:00-12:00 and 13:00-17:00 JST, Monday through Friday

(excluding national and corporate holidays)