Surface evaluation

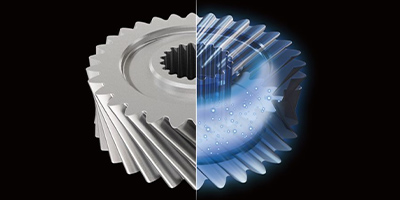

Sightia™ surface evaluation technology

Visually track invisible forces (stress) acting on surface layers to prevent damage and defects

Sinto’s contactless, nondestructive evaluation technology is able to identify the internal state of products before and after heat treatment and after shot peening. Measurements are done quickly, allowing for automated inspection as well as quality management for individual pieces in addition to conventional process management.

We have harnessed our extensive knowledge, experience, and skills to create this proprietary technology capable of inspecting all pieces at a fraction of the time, cost, and labor—saving our customers money while ensuring reliable quality.

Applications

- Detects insufficient shot peening treatment

- Detects heat treatment errors

- Identifies contaminants

- Detects processing distortions

- Detects polishing/grinding burns

- Detects changes in residual stress on welded joints …and more

Target products

- Shot peening products

- Heat-treated products

- Welded products …and more

CMRS residual stress reference pieces

Accurately measures residual stress

The use of CMRS makes it easy for anyone to get accurate measurement results. These pieces can also be used to check bulk stress value ranges for items with the same composition.

Applications and benefits

Lineup for stress measurement

Varied lineup offers stress measurement using different combinations of machining processes, materials, and stress values

No difficult measurement principles

Just use the CMRS to confirm your measurement device’s output accuracy

Easy maintenance

Just check using the CMRS prior to daily inspections to make sure your measurement device is functioning properly

Detect differences in measurement devices or methods

Verify the reliability of new measurement devices when considering device replacement

Detect measurement problems

Rapid detection of worn-out bulbs or other problems affecting output value accuracy

Please consult us for inquiries.

+81-52-581-6896

Available hours: 9:00-12:00 and 13:00-17:00 JST, Monday through Friday

(excluding national and corporate holidays)