Surface treatment equipment lineup

Get exactly the treatment effect, shape, and other surface criteria you need through our extensive targeted surface processing options.

Surface processing options

| Remove |

Peel |

Roughen |

Polish |

Strengthen |

Micromachine |

See |

|

|---|---|---|---|---|---|---|---|

| Shot blasting | ○ | ○ | ○ | ○ | |||

| Air blasting | ○ | ○ | ○ | ○ | |||

| Barrel polishing | ○ | ○ | ○ | ||||

| Brush polishing | ○ | ○ | |||||

| Microblasting | ○ | ○ | ○ | ○ | |||

| Surface evaluation | ○ | ||||||

| Processing services | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

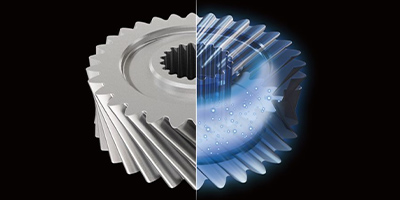

Shot blasting

Motorized blades rotate at high speeds, shooting out blasting abrasives using centrifugal force. This approach efficiently treats broad surfaces, making it optimal for large products or high-volume treatment processes.

Treatment effects

- Surface roughening

- Deburring

- Descaling

- Removal of impurities

- Shot peening …and more

Table

For long, high-mix, small-lot, or heavy workpieces

Drum

For small, thin, or large-lot workpieces

Rubber apron

For small-to-midsize and large-lot workpieces

Hanger

For small-to-midsize workpieces

Monorail

For large/heavy workpieces

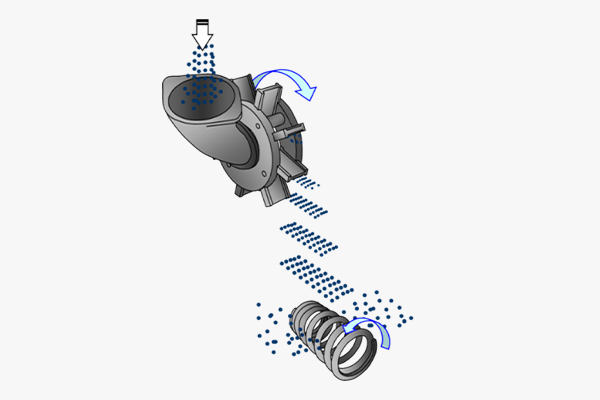

Air blasting

Air blasting uses compressed air to shoot blasting abrasives out of a nozzle. It works best for localized treatment.

Treatment effects

- Surface roughening

- Deburring

- Descaling

- Removal of impurities

- Removal of adhesions

- Patterning

- Shot peening …and more

Gravity suction

General-purpose

Table

Multi-table

Track

Tumbler

Apron

Conveyor

Robot

Autofeed

Table

Direct pressure

Table

Blow

Tumbler

Shot peening equipment

Just one piece of equipment does everything from shot peening to surface evaluation for more reliable quality control.

Treatment effects

- Shot peening

- Surface evaluation …and more

ISPX-S

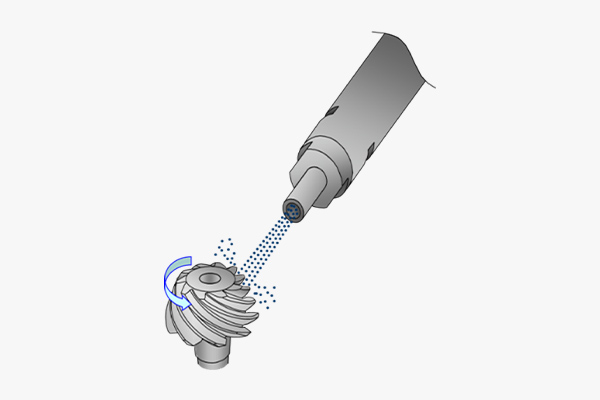

Microblasting

Our fixed-rate feeder blasts a steady stream of fine shot to deliver the precise processing needed for electronics and other delicate components.

Treatment effects

- Micromachining

- Surface roughening

- Patterning …and more

Gravity suction

MB

Direct pressure

ELP

Fine powder suction

SSN

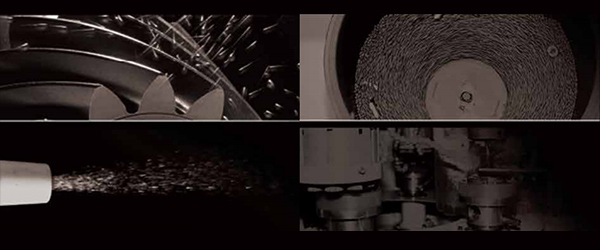

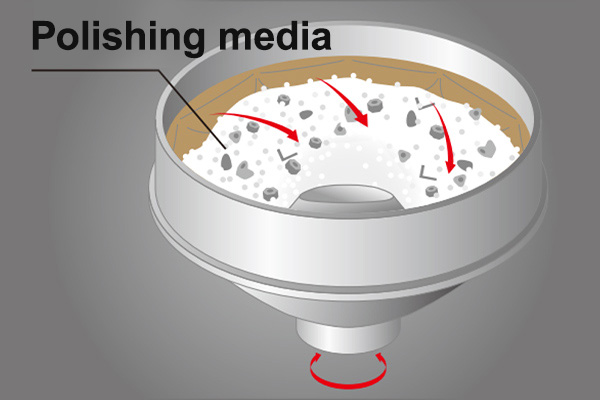

Barrel polishing equipment

Barrel polishers apply physical pressure to grooves filled with polishing media and products to be treated, polishing by generating friction between the two. They are ideal for batch treatment.

Treatment effects

- Deburring

- Rounding

- Glaze finishing

- Smooth polishing

- Descaling …and more

Wet barrels

Flow

Centrifugal

Vibrating

Ancillary equipment

Dry barrels

Rotating

Flow

Centrifugal

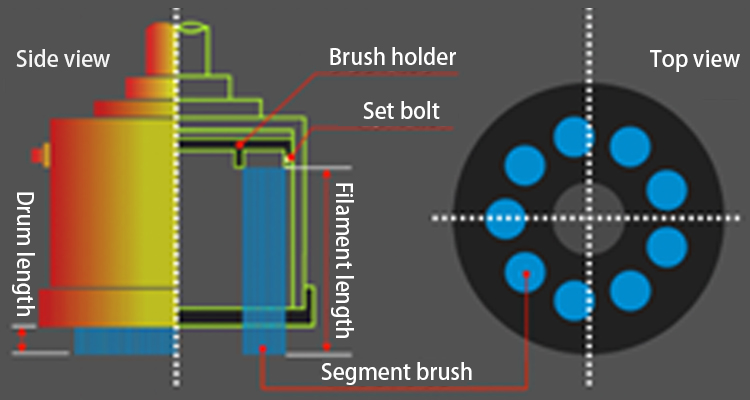

Precision brushing equipment

These machines rotate brushes at high speed, rubbing the tips of the bristles against the target products to finish the edges. They are best suited to treating single workpieces.

Treatment effects

- Deburring

- Rounding

- Smoothing …and more

Conveyor

Table

Centerless

Flat surface finishing

Specialty equipment

For diecast products

For plastic products

For paint stripping

For steel (H-beams)

For steel (steel plates)

Please consult us for inquiries.

+81-52-581-6896

Available hours: 9:00-12:00 and 13:00-17:00 JST, Monday through Friday

(excluding national and corporate holidays)