Foundry

Better casting production

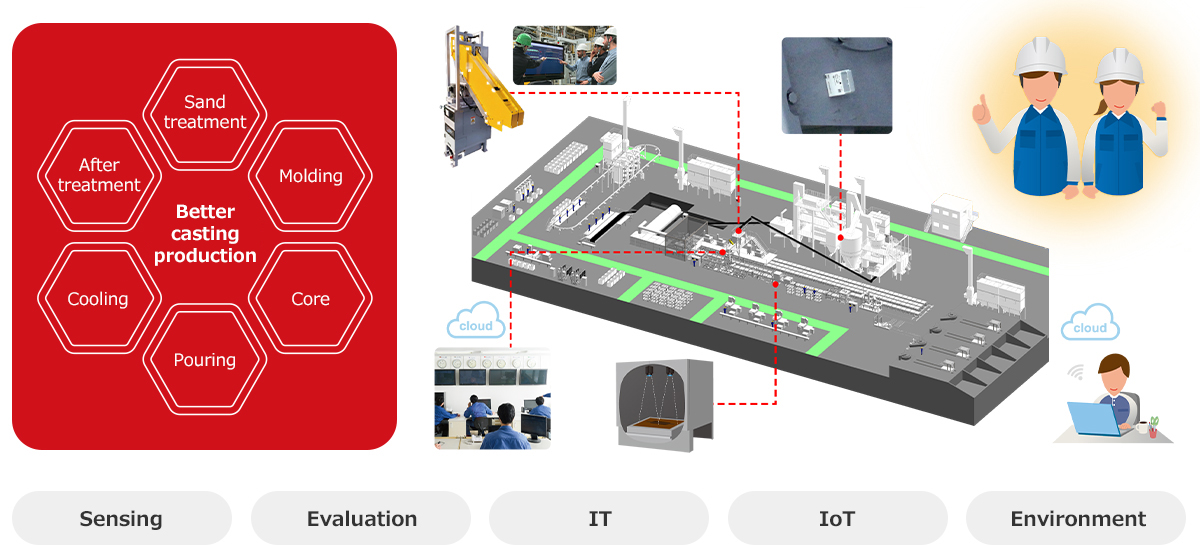

Sinto crafted Japan’s first domestically-made molding machine, and since then has been ceaselessly developing innovative technologies that add value to casting products—and in the process, charting a new course for foundry history. Today, our initiatives for net-shaping, thinning/weight reduction, and zero defects continue to take the industry forward into the next generation, resulting in casting production that is worker- and environment-friendly. Through this evolution, we continue to be world leaders in foundry operations.

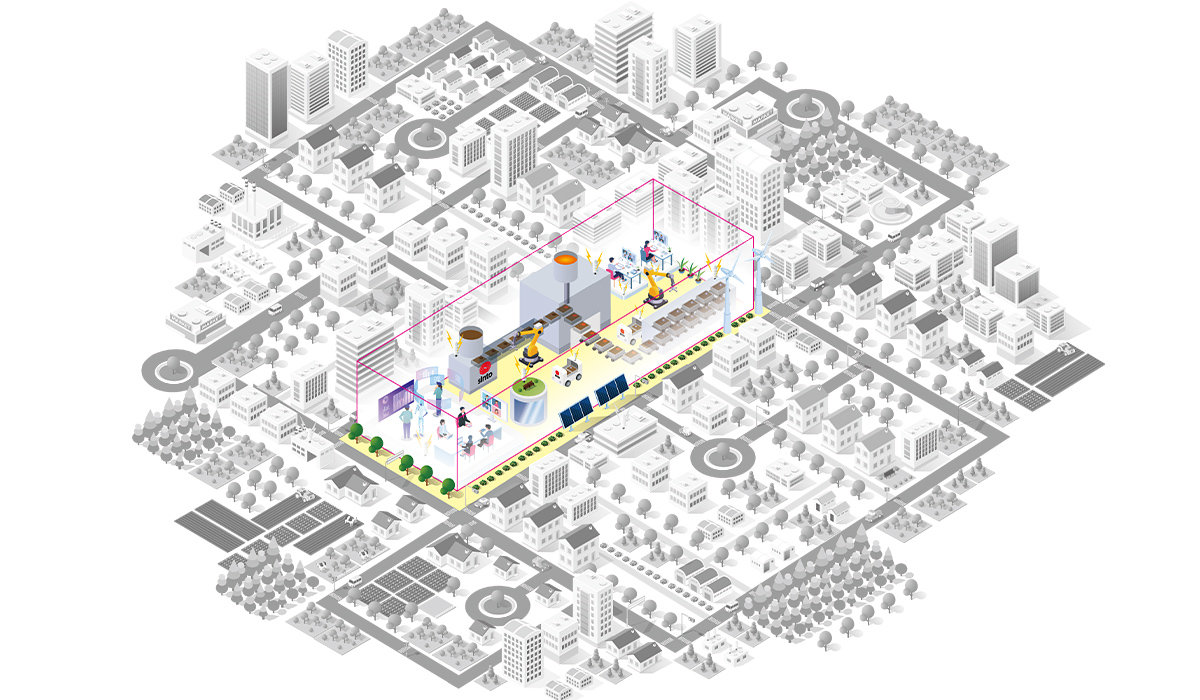

The ideal foundry that Sinto aims for

Contributing to the happiness of

local communities and factory workers,

and to the production of castings

that make customers happy

Make people glad

Make people lively

Make people smile

Contributing to the happiness of local communities and factory workers, and to the production of castings that make customers happy

- Make people glad

- Make people lively

- Make people smile

1.Great foundries to work in

Safe, comfortable work environment

- Step-free floors for added safety

- Dust-free work environment

- Odor-free work environment

Easy operations

- Reduced melting, core setting, and deburring work

Flexible working styles

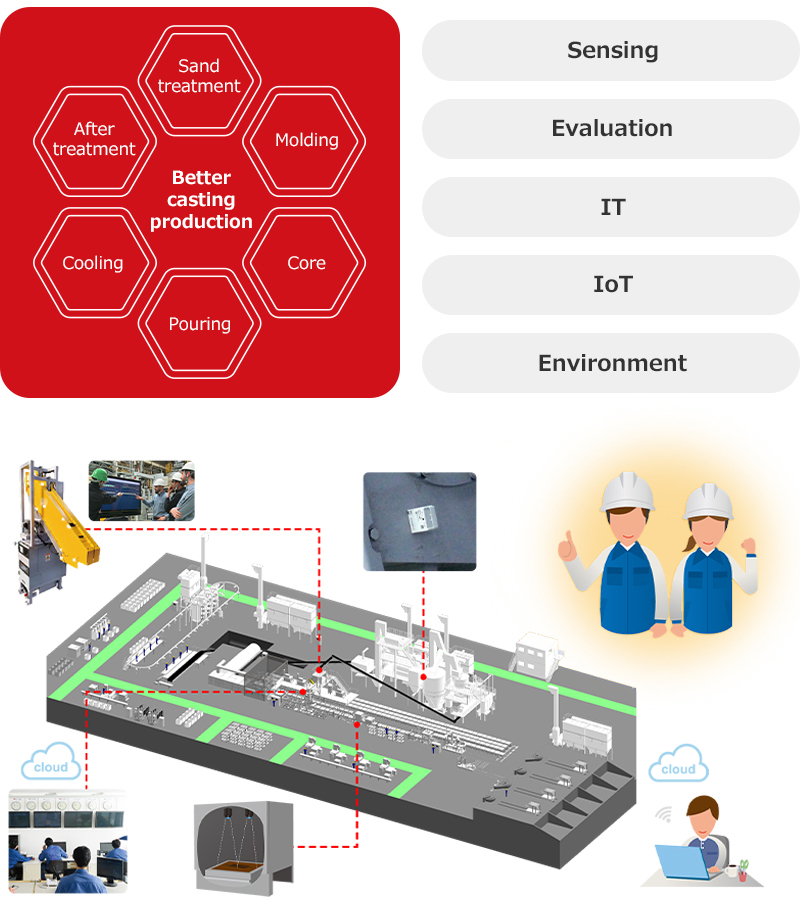

- Visualization of operations and product information anytime, anywhere

2.Enriching foundries

Sinto works to create foundries that are a source of enrichment for local communities. We are always coming up with new initiatives to make foundries better.

3.Support for casting production

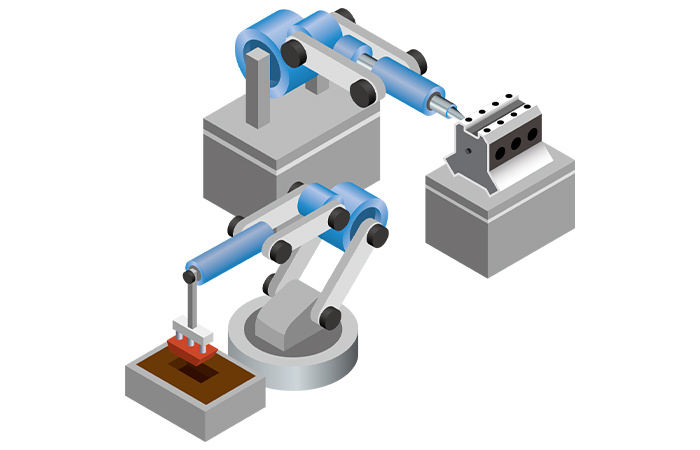

Sinto uses IoT technology to support our customers’ casting operations.

Net-shaping and thinning/weight reduction

Our advanced molding technologies deliver precision dies, achieving near-net shaping and thinning/weight reduction.

Aiming for zero defects

Our evaluation sensors collect manufacturing data from every process in casting production for advanced digitization, collection, and visualization. This makes it possible to understand the situation in real time and analyze data to identify the root cause of defects. Sinto takes casting production to the next level with quality built into each process, keeping defects from moving downstream.

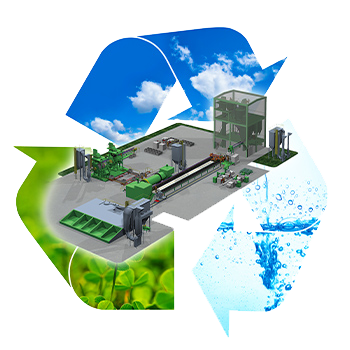

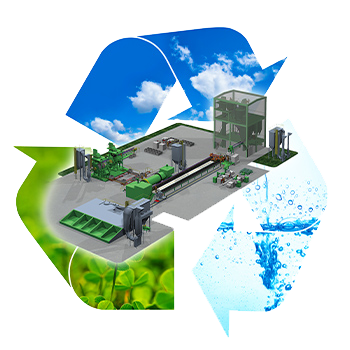

Eco-friendly, people-friendly casting production

We contribute to the evolution of foundries that are worker- and environment-friendly. Sinto proposes solutions to provide a clean, comfortable work environment and automated solutions that reduce operator load at every process.

Sinto provides proprietary technologies and IoT tools across six foundry processes to deliver comprehensive solutions for better casting production

In pursuit of eco-friendly casting production

- Clean environment with minimal sand spills and dust dispersion

- Odor-free

- Recycling for reduced resource consumption

- Foundry sand recycling and more

Product information

We offer an extensive product lineup based on customer goals, environmental considerations, and target processes to provide the products that are right for you.

Search by casting process

To meet a variety of production needs

To meet the needs of various production approaches for different products and production volumes using a wide range of casting processes, we offer a combination of optimal process proposals and IoT-powered solutions. We provide a unique production system in support of casting production, improving quality and productivity while reducing labor and making foundries friendlier for operators.

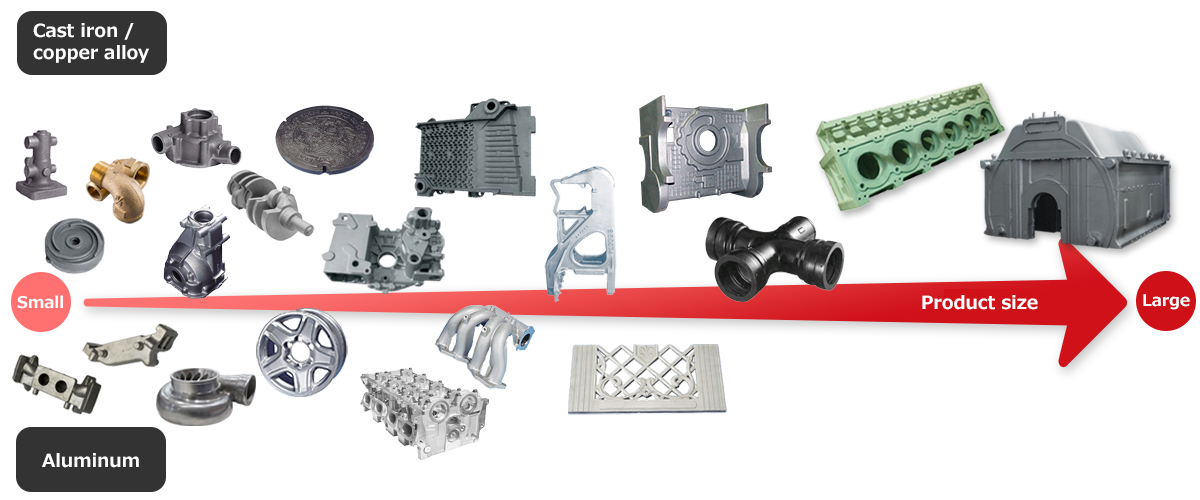

Search by material/casting size

- materialCast iron/copper alloy

- SmallGreen sand molding

- MidsizeV-Process molding

- LargeChemically bonded

- materialAluminum

- Each sizeAluminum casting

Please consult us for inquiries.

+81-52-581-6896

Available hours: 9:00-12:00 and 13:00-17:00 JST, Monday through Friday

(excluding national and corporate holidays)