Exhaust gas treatment

Hazardous gas treatment systems used in

a wide variety of fields

Sinto began releasing information about emissions of specified chemical substances for each of its business locations in 2003. The following year, Japan’s Air Pollution Control Act was revised, putting VOC emissions reduction in the spotlight. Odors have also been subject to regulations under the Offensive Odor Control Law in recent years, making it necessary to address complaints from the local community.

Sinto’s exhaust gas purification systems are low-energy, high-efficiency systems capable of decomposing VOCs and targeting odors while effectively utilizing heat energy.

Sinto offers total engineering of exhaust gas treatment systems that reduce running costs.

These systems are eco-friendly.

- Economical

- Spectacular decomposition efficiency

- Reduced environmental

impact

Product information

- Regenerative thermal exhaust gas purifier

-

Greatly reduces fuel consumption

- Regenerative catalytic exhaust gas purifier

-

Combines regenerative and catalytic performance to greatly reduce energy costs

Eco-friendly, energy-efficient system engineering

Energy-efficient system for exhaust gas treatment

Our regenerative thermal oxidizers (RTOs) have a definitive advantage over direct-heat systems in terms of both environmental and cost performance, and running costs and environmental impact are further reduced with the addition of ancillary equipment.

The 3Rs of exhaust gas treatment

Reduce the amount of gas to be treated

Concentrators reduce volume of CO2 emissions

① VOC concentrators

Our systems can be fitted with concentrators to target high-flow, low-concentration VOC gas. By increasing the concentration of VOCs and reducing the overall airflow to be treated, this contributes to reduced fuel consumption and lower CO2 emissions.

Reuse heat energy

Heat exchangers send heat to drying lines

② Heat exchangers

Add a heat exchanger to reuse the heat from treated high-temperature gas. The hot air is perfect for supplying to drying furnaces or other drying operations, allowing for energy savings throughout the entire production line.

Recycle heat energy

Waste heat boilers recycle heat energy as steam

③ Waste heat boilers

These devices effectively recycle treated high-temperature gas by converting it to steam energy. Reducing the operation of fuel-burning boilers can result in significant CO2 reductions.

Exhaust gas purification technologies

Regenerative thermal oxidizers (RTOs) (excludes ECRs)

Organic odors and volatile organic compounds (VOCs) can be efficiently burned and decomposed at temperatures of 800ºC and higher. RTOs use a honeycomb ceramic structure for thermal storage, resulting in extremely high heat exchange efficiency. This greatly reduces running costs compared to direct-heat equipment, which requires a constant supply of fuel.

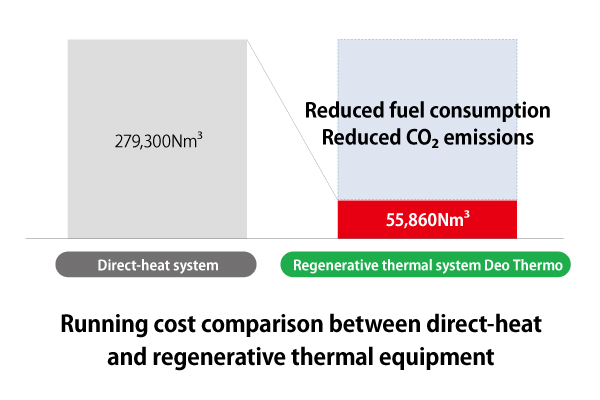

Running cost comparison between direct-heat and regenerative thermal equipment*

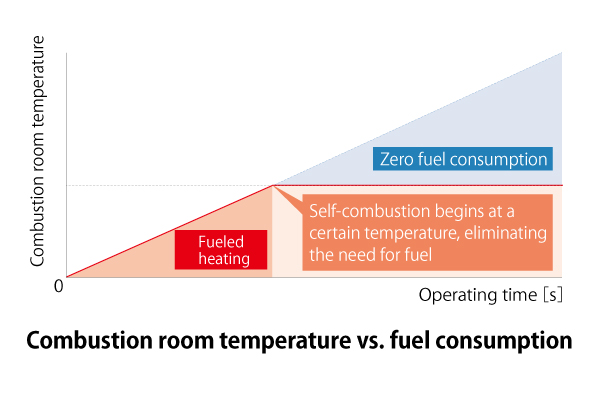

VOCs will self-combust at a certain concentration and combustion room temperature, making it unnecessary to supply combustion fuel. This is how Sinto is able to bring the running costs needed to decompose VOCs to zero, greatly reducing fuel consumption. It’s the perfect solution for customers looking to cut costs while reducing CO2 emissions.

*Annual (6,000-hour) LNG consumption when treating 150 ppm of toluene at 100 Nm3/min

Proprietary honeycomb ceramic structure

Sinto’s proprietary design maximizes contact surface area for outstanding heat exchange efficiency while supporting straight-line gas flow that minimizes pressure loss as well as tar adhesion.

Please consult us for inquiries.

+81-52-581-6896

Available hours: 9:00-12:00 and 13:00-17:00 JST, Monday through Friday

(excluding national and corporate holidays)