Dust collection

Dust is everywhere in industrial plants

What we collectively term “dust” is actually an endless array of particles of varying concentrations, weights, temperatures, compositions, and other characteristics generated during industrial work and processes.

Sinto is one of the top sellers of dust collectors in Japan, and we apply our extensive technology, experience, and expertise in engineering superior dust collect systems. Whether you’re looking to collect dust throughout a plant or in specific work areas, Sinto systems bring added environmental performance, workability, and safety to your workspaces.

Product information

- General-purpose dust collectors

-

Collects a wide range of dust types generated at production sites

Best for:

Metal, food, pharmaceuticals, animal feed, fertilizer, resins, minerals, cement

*For use with non-explosive particles only

- Dust collectors for explosive particles

-

Give your workers safety and peace of mind with our general-purpose dust collectors for explosive particles.

Best for:

Metal, food, pharmaceuticals, resins, minerals, coatings, and more

- Dust collectors for fumes

-

Dust collectors designed to trap ultrafine fumes for a more comfortable work environment

Best for:

Metal fumes

- Dust collectors for oil mist

-

Powerful supplementary equipment for highly-concentrated mists

Best for:

Water-based oil mists

Systems

Sinto dust collection systems

Eco-friendly equipment

Sinto’s eco-friendly equipment helps eliminate wastefulness to support energy-efficient operations

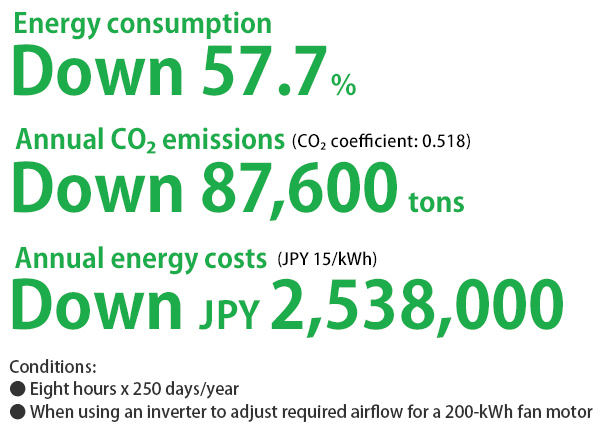

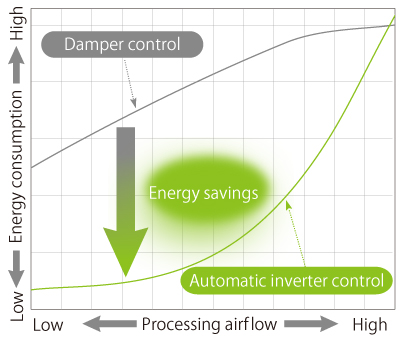

Fans: Frequency control

Our dust collectors use inverters to control processing airflow. This results in lower energy consumption and CO2 emissions compared to damper-adjusted airflow systems.

Monitor emissions cleanliness

Monitor not only the work environment but also the local environment

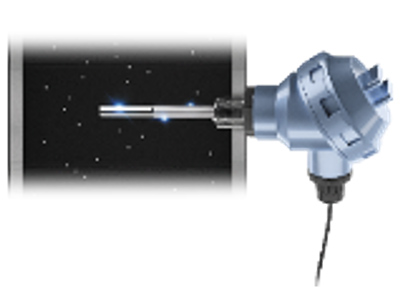

Dust leak sensors

Monitor the concentration of particles in the exhaust gas generated from our dust collectors. Detects minute dust concentrations invisible to the naked eye, allowing customers to rapidly identify filter problems or blower leaks and prevent the spread of damage caused by scattered dust.

Immediately detect fires during dust collector operations

Early fire detection system

Dust leak sensors

These sensors identify dust leaks caused by burned or torn filters and put out a signal for abnormalities, for effective detection of fires during dust collector operations.

Smoke sensors

These sensors identify smoke from fires and put out a signal for abnormalities, for effective detection of fires when dust collectors are not in motion.

Temperature sensors

These sensors detect temperature increases inside the dust collector due to fire and put out a signal for abnormalities.

Put fires out immediately to prevent burn damage

Fire prevention equipment works in conjunction with early fire detection systems.

Fire-resistant filters

Sinto filters offer superior fire resistance to keep fire from spreading within them.

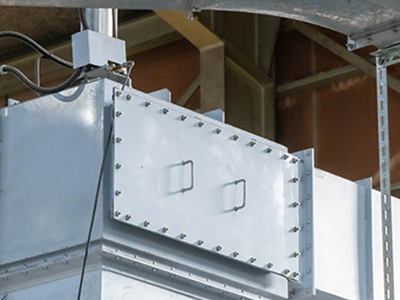

Intake/exhaust cutoff damper

Should a fire occur, our dust collectors immediately cut off intake/exhaust to prevent outside air from entering the machine, cutting off oxygen and helping to extinguish the fire.

Fire extinguishers

Dust collectors are fitted with blowers or sprayers capable of shooting out inert gas (such as N2) to prevent fires from spreading.

Ducts stay clean

Dust accumulation in ducts can cause falling objects or fires.

Fans: Automated steady airflow control

Inverters adjust our dust collector fans to maintain a consistent intake airflow (airspeed within ducts). This prevents dust accumulation in ducts caused by unintended drops in airflow volume, enabling safer, steadier dust intake.

Dust accumulation sensors

Our dust collectors detect dust accumulation in intake ducts for rapid detection of abnormalities and better preventative maintenance.

Duct inspection ports

Inspection ports allow workers to visually check for dust accumulation in intake ducts and clean them out as needed.

Static electricity prevention

Static electricity generated by dust friction can create sparks that can lead to fires or explosions.

Bonding

Friction in intake dust can generate static electricity that sparks a dust explosion or fire. Our dust collector units and intake ducts are fitted with conductive flanges that ground the entire device to release static electricity.

Antistatic filters

Our filters are made of conductive materials that carry away static electricity caused by friction generated when filtering out or cleaning off dust.

Protecting workers from dust explosions

Our dust collectors are also designed to physically protect workers in the rare event of a dust explosion.

Blast diffusion port

Should a dust explosion occur, blast diffusion ports limit damage to the dust collector by releasing the impact of the blast in a safe direction.

Blast-cushioning damper

Should a dust explosion occur inside the dust collector, backflow prevention dampers are set up to keep the blast from escaping out of the intake ports.

Keeping dust collectors clean, inside and outside

When working with dust collectors, the first step toward safety is preventing dust buildup in the hopper.

Bridge breakers

Adhesive and fibrous particles form bridges inside dust collector hoppers, which can prevent them from being expelled normally. Applying shocks or vibration to the dust accumulated in the hopper controls this buildup so that the dust flows through properly.

Hopper level gauge

Hopper level gauges identify dust buildup in the hopper and put out a signal if an abnormality is detected.

Ancillary equipment

Efficient dust collection

Dust is generated in all kinds of processes and environments. Sinto offers the optimal hood shape to efficiently prevent the spread of dust in your particular application.

Quieter operation

We keep fan noise to a minimum by encasing our blowers in soundproof boxes and passing exhaust through mufflers with advanced sound-damping performance.

Cleaner exhaust

Our dust collectors are fitted with secondary filters in the final processes, generating cleaner exhaust.

Low-odor exhaust

Deo Thermo: Regenerative thermal device breaks down and removes volatile organic compounds (VOCs) and odors in exhaust gas for exceptional decomposition efficiency and low running costs

Activated carbon adsorption tower: Uses activated carbon to trap and remove malodorous components from dust collector exhaust

For high-temperature gases

Cooling tower: Cools high-temperature gas emitted from melting or combustion furnaces and sends it to the dust collector at or below its normal heat-resistant temperature

For coarse particles

Our dust collectors can be fitted with a pretreatment device to protect filters from excessive wear due to coarse particles, extending their life. The cyclone design also helps remove heat energy from sparks.

Filter protection and enhanced dust cleaning performance

Precoating device: Sprays deactivator (filtering aid) into intake gas to prevent fires from spreading to the dust caught on filters

Technologies

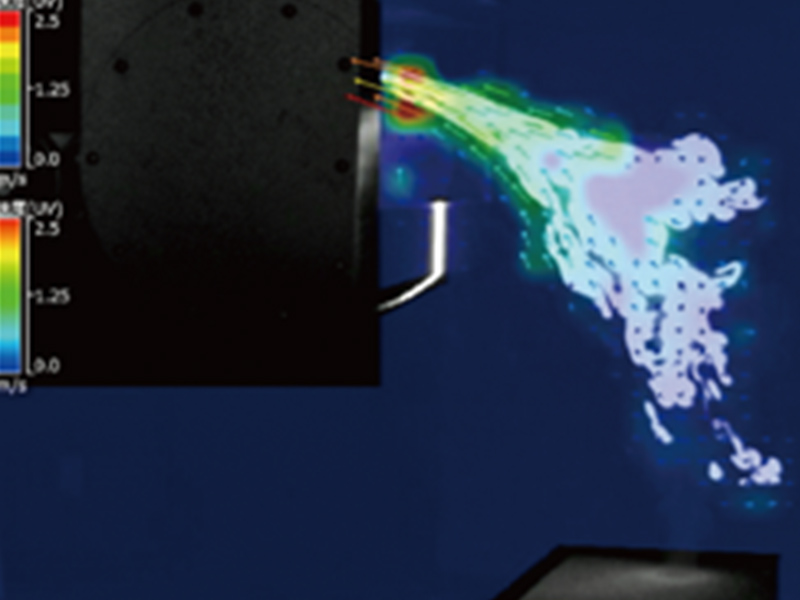

Airflow control technology

Smoke and dust are generated all over industrial plants, negatively impacting workers and the environment.

Sinto technologies are designed to prevent smoke and dust from spreading by efficiently trapping them and carrying them off to designated locations.

By mapping out airflow patterns and selecting the right hoods and ducts, we can effectively control airflow in the work environment.

Dust explosion and fire prevention technologies

With the increasing utilization of functional fine particles in recent years, there is also an elevated risk of explosions and fire.

Dust fires and explosions pose grave risks to onsite workers and can cause major losses for companies as well.

At Sinto, we have the knowledge and technology to make your workplaces safer and more comfortable for everyone.

Please consult us for inquiries.

+81-52-581-6896

Available hours: 9:00-12:00 and 13:00-17:00 JST, Monday through Friday

(excluding national and corporate holidays)