What is polished concrete?

Polished concrete is a new flooring technology developed in the US.

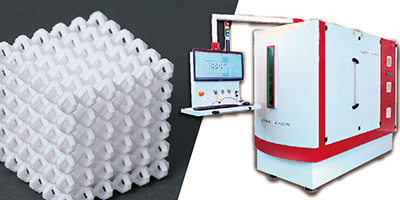

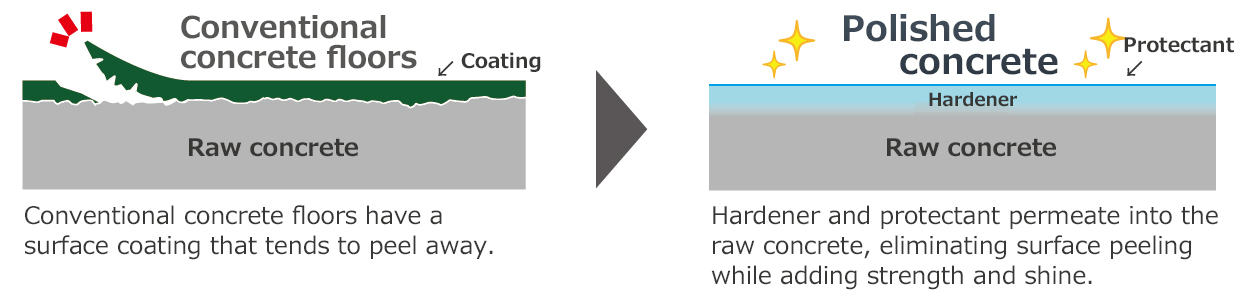

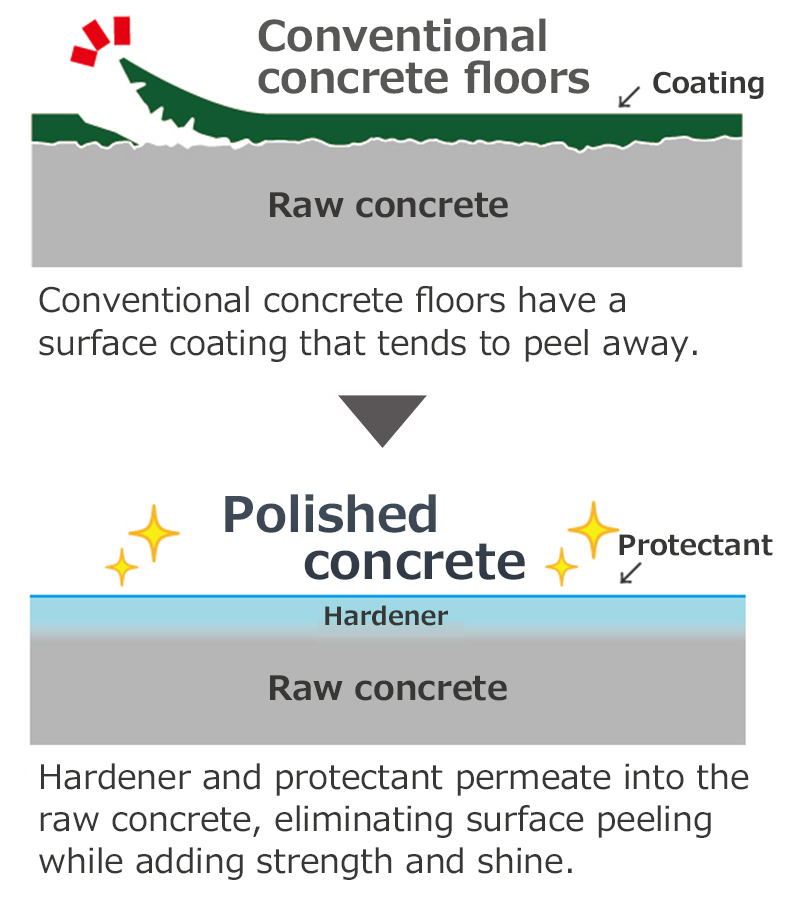

It involves grinding and polishing concrete flat, applying a penetrant chemical known as a hardener, and then polishing the surface smooth.

A protectant is then applied to the finished product, which repels dirt and adds luster, bringing out the natural beauty of the concrete.

The technique can be applied to existing concrete surfaces as well as new installations, transforming old floors into something completely fresh and new.

And because polished concrete does not degrade or peel with time, it stays beautiful for years with almost no maintenance, greatly reducing repair costs.

Sinto offers both concrete polishing services and the materials needed for polished concrete.

A hardener is soaked into the raw concrete surface to strengthen it

Polished concrete process

Features

-

No peeling

Non-deteriorating surfaces that stay flat and prevent falls, for added safety and semi-permanent durability

-

Durable

Highly-refined concrete surface with superior wear resistance

-

Lustrous shine

Brightens spaces and shows off merchandise

-

Flat

Zero surface deformation means that floors stay flat for easier cart maneuvering

-

Clean

Protectant resists dirt for an easy-to-clean surface

-

Cheap to maintain

Resists dirt and wear for low maintenance costs, year after year

Example applications

Functional floors

Durable surfaces do not degrade or peel, so they stay perfectly flat.

Easy transport and cleaning create safer spaces that are easier to work in.

▲Equipment storage

▲Plants and warehouses

Beautiful floors

The lustrous, high-quality finish of polished concrete shows off your products in their best light.

Choose from any number of finishing styles to complement the look and feel of your retail space.

▲Car showrooms

▲Building entryways