Aluminum casting

Engineering of comprehensive systems for every aluminum casting process.

High-quality, high-yield production that enables automation and labor savings.

Sinto’s aluminum casting production is friendly to workers and the environment.

In pursuit of better aluminum casting production, Sinto’s casting equipment lineup offers higher-quality products with higher productivity, designed with worker safety in mind.

From core equipment to finishing equipment, handling equipment, and environmental equipment, our aluminum casting systems offer comprehensive engineering solutions that help customers meet their automation and labor-saving goals.

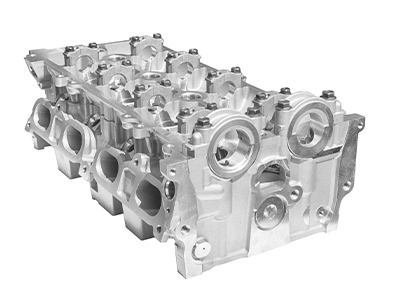

Aluminum casting technology that delivers superior dimensional accuracy

Usage examples

▲Aircraft engine parts

▲Automotive engine parts

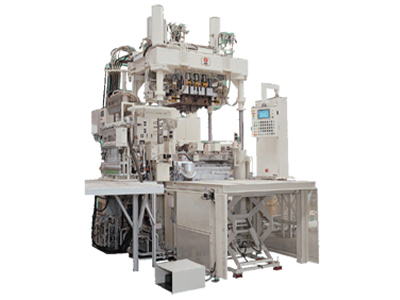

Aluminum casting machines designed for reliable production of high-precision, high-quality aluminum products

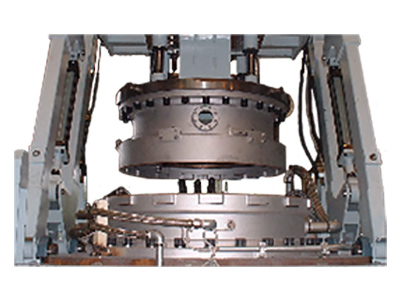

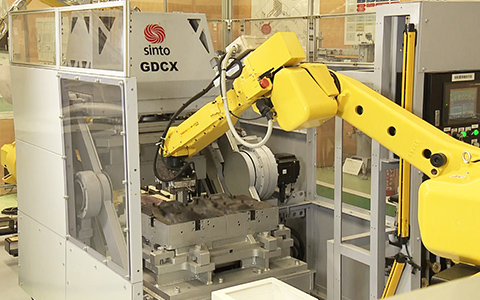

▲Tilting gravity diecasting machine GDCX

▲Low-pressure diecasting machine LPD

▲Differential pressure diecasting machine SAAT

Core molding systems for improved aluminum casting production and environmental performance

Cores are at the heart of casting. At Sinto, our systems don’t just produce high-quality cores, they also minimize odors so they’re better for workers and the environment.

We provide advanced engineering solutions for core molding systems that automate core production while saving labor.

Optimized core processes for all of our customers’ needs

- Cold box molding

- Inorganic cores

- LYTECORE™

- Shell molds

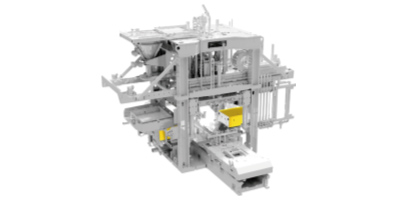

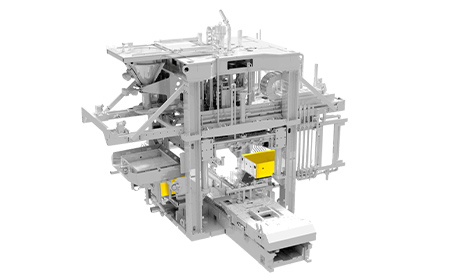

Cold box automatic core molding machine series

For low-odor, worker-friendly core molding processes

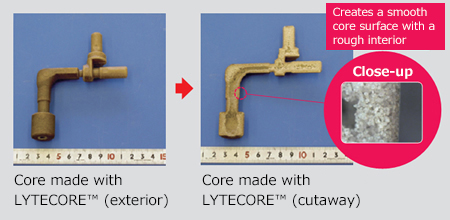

LYTECORE™ core molding process

Core molding for complex shapes

Enables core molding for complex shapes through pressurized dies using foaming binder sand.

The LYTECORE™ process is also virtually odor-free, making it better for the environment.

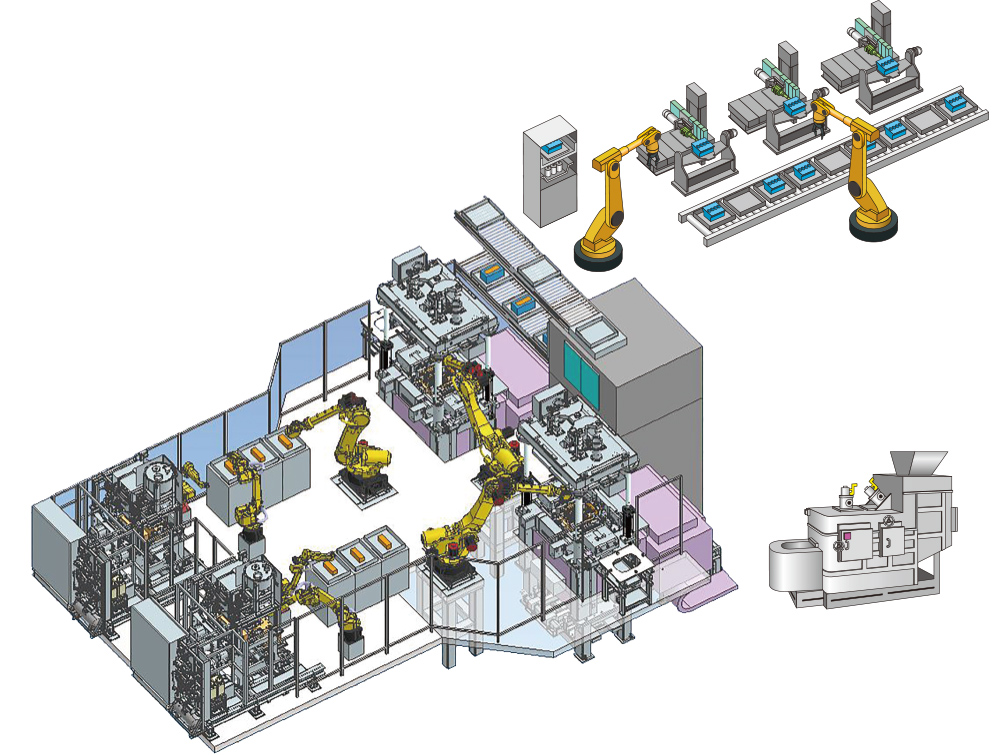

Total system engineering for aluminum casting production

Sinto’s total engineering solutions automate and save labor at every stage of aluminum casting production, including melting, core molding, aluminum casting, cooling, shake-out, sand reclamation, after treatment, and finishing.

Aluminum casting machines

Reliable production of quality aluminum castings

Sinto gravity and low-pressure casting machines reduce defect rates for reliable production of high-quality aluminum castings. Through our extensive lineup, we provide the right aluminum casting machine to meet our customers’ needs.

Core machines/sand reclamation

For low-odor, worker-friendly core molding

Cores are at the heart of casting. At Sinto, our systems don’t just produce high-quality cores, they also minimize odors so they’re better for workers and the environment. Our total core systems provide automated core operations, labor-saving engineering, core sand reclamation systems, and more for cold box molding, inorganic cores, and shell molds.

Aluminum after treatment and finishing

Everything from finishing to surface treatment for aluminum castings

Sinto offers total after treatment solutions for aluminum castings, from finishing processes like gate cutting, deburring, surface machining, and making holes to surface treatment processes such as core sand shake-out and cleaning.

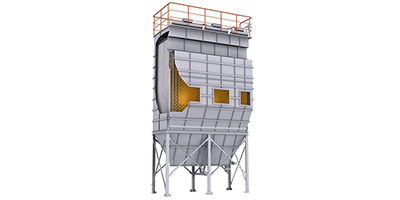

Environmental equipment for aluminum casting

Environmental equipment that is worker- and environment-friendly

Sinto’s environmental solutions keep aluminum foundries clean and safe for better working conditions.

Please consult us for inquiries.

+81-52-581-6896

Available hours: 9:00-12:00 and 13:00-17:00 JST, Monday through Friday

(excluding national and corporate holidays)