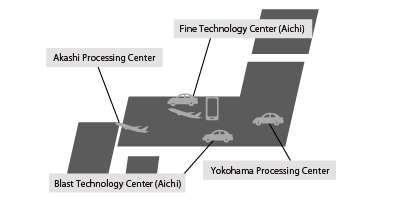

Applications and usage examples

- Search by surface function

- Search by processing effect

Reduce weight

Strengthen

Automobiles

Use shot peening to reduce the weight of suspension springs

Reduce energy loss

Polish

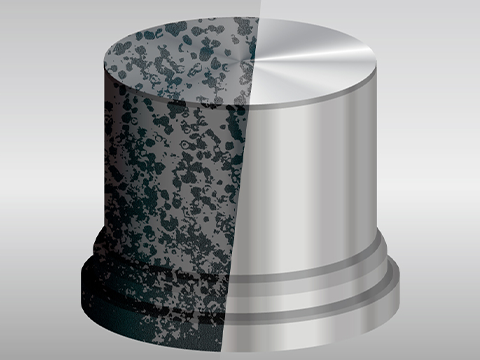

Bearings

Use oil-reservoir processing to improve the sliding performance of bearing rollers

Increase yield

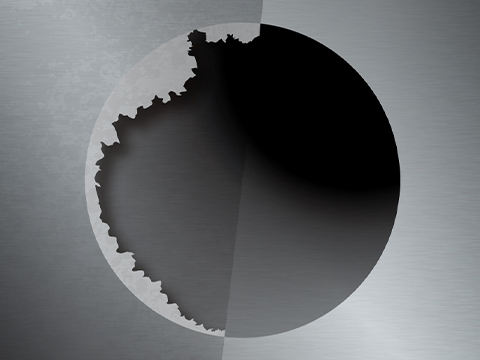

Peel

Electronics

Remove the damaged layers of wafers to increase yield

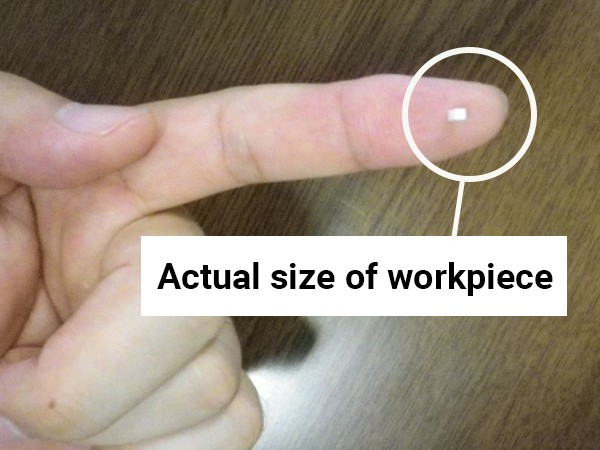

Deburr

Remove

Electronics

Use a powder suction process to deburr micro-products

Create peel-resistant coating

Roughen

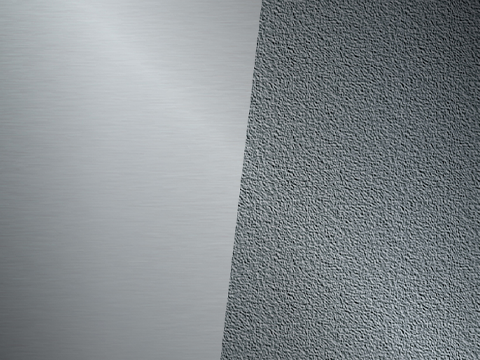

Shipbuilding

Use shot blasting on steel plates for ships for surface roughening

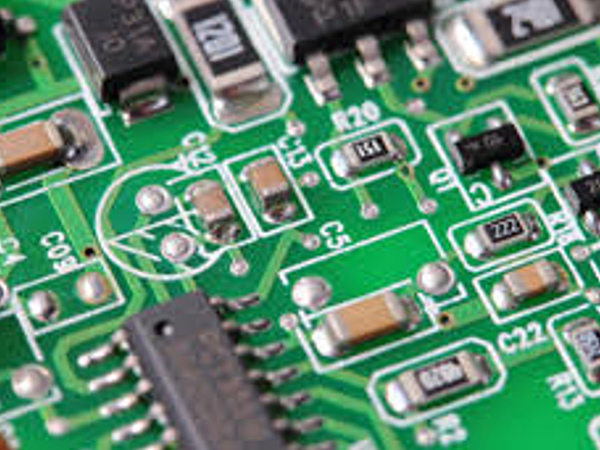

Process printed circuit boards

Microprocessing

Electronics

Use microblasting on printed circuit boards for damage-free fine-hole processing

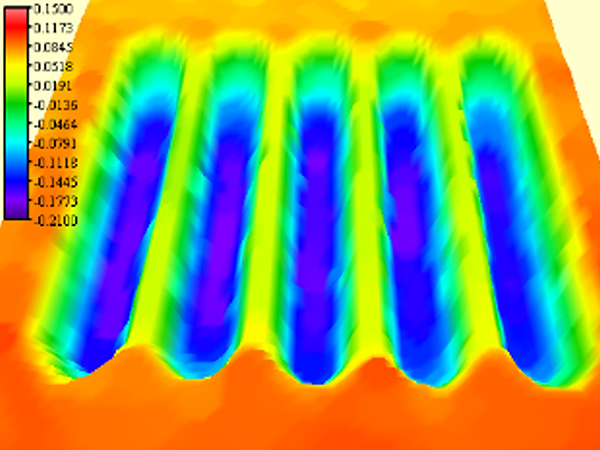

Visually track effects

See

Test/measure

Use X-ray stress measurement to visually track all peening stress values

Prevent joint loosening

Roughen

Steel frames

Use shot blasting on steel frame members to roughen their surfaces for the optimal sliding coefficient

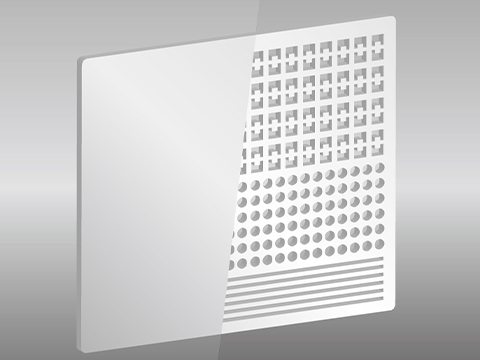

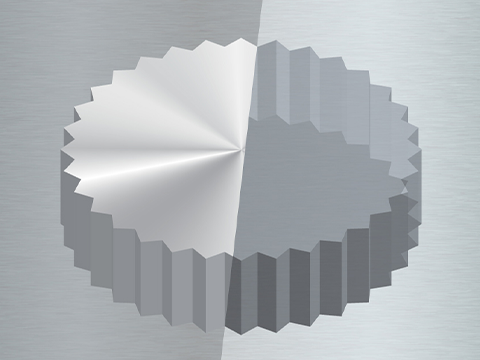

Stabilize deposition quality

Microprocessing

Electronics

Use precision embossing on electrostatic chucks to ensure uniform pin height

Remove scaling

Peel

Forging/heat treatment

Use shot blasting on heat-treated products to remove scaling

Deburr

Remove

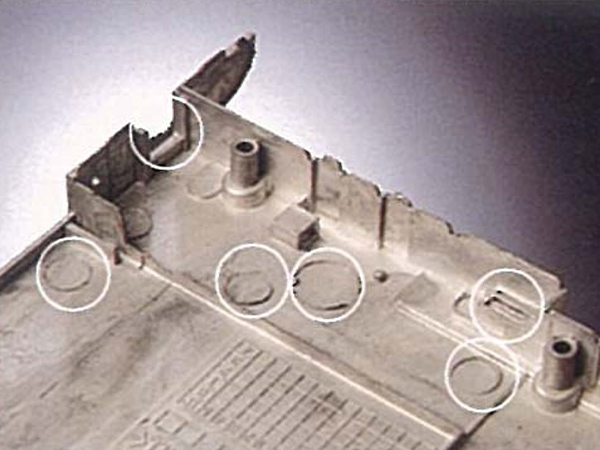

Diecasting

Use shot blasting on thin-walled products for strain-controlled deburring

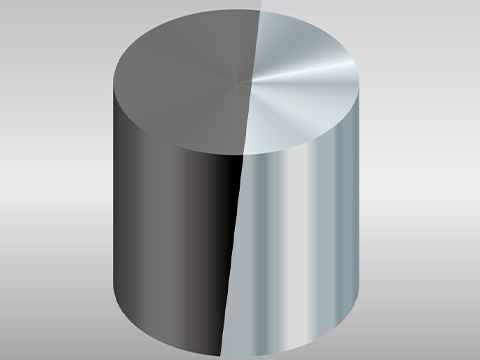

Reduce friction coefficient

Polish

Compressors

Smooth-polish compressor vanes to improve sliding performance

Add traceability

See

Test/measure

Use non-destructive testing for total in-line testing of peening process aptitude

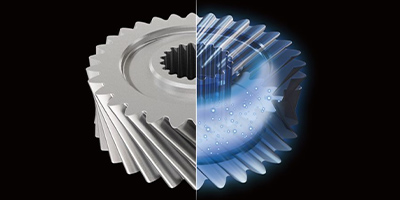

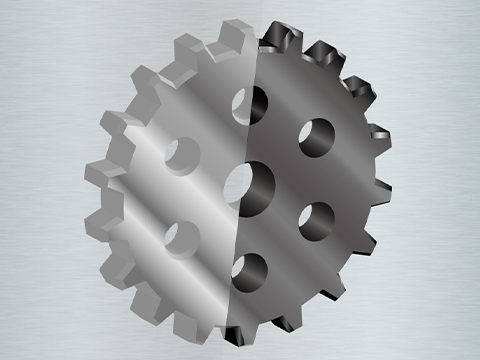

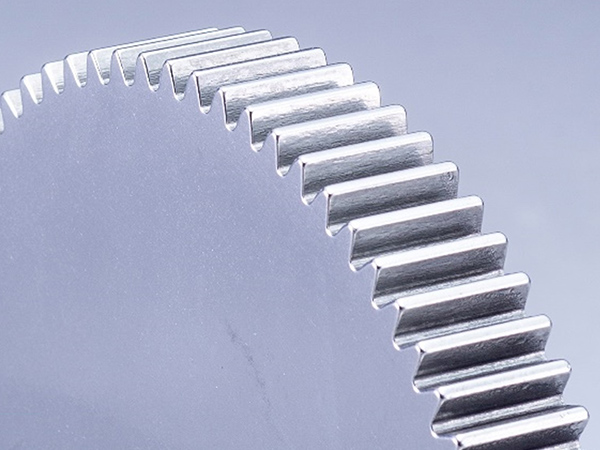

Lengthen product life

Strengthen

Automobiles

Use shot peening on gears to prevent cracking

Remove scaling

Peel

Wire

Use shot blasting on wire to remove scaling

Improve coating adhesion

Roughen

Commodities

Use air blasting on golf balls for roughening

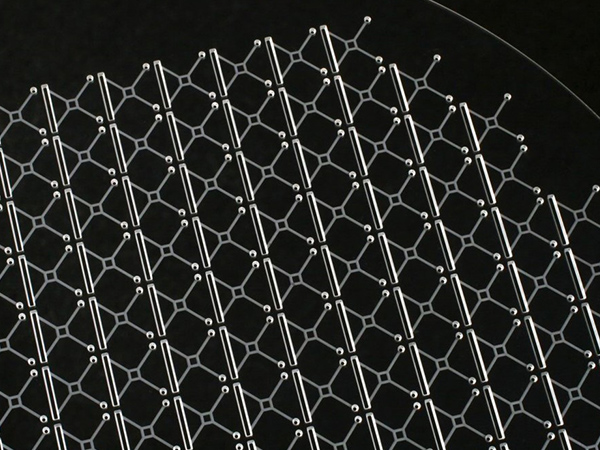

Precision wafer processing

Microprocessing

Electronics

Use microblasting on electronic substrates for hole and groove processing

Deburr

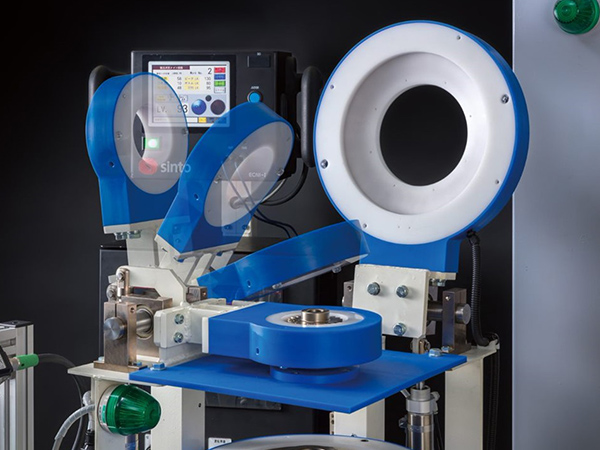

Remove

Automobiles

Use planetary brush polishing on thin press products to deburr the ends

Check effectiveness criteria

See

Test/measure

Use stress reference pieces to improve the reliability of X-ray stress measurements

Ensure reliable quality

Strengthen

Automobiles

Use shot peening to increase the rigidity of plate welding

Smooth complex shapes

Polish

Gears

Use a smoothing process on gears to smooth out complex shapes

Remove foundry sand

Peel

Casting

Blast casting parts to remove foundry sand

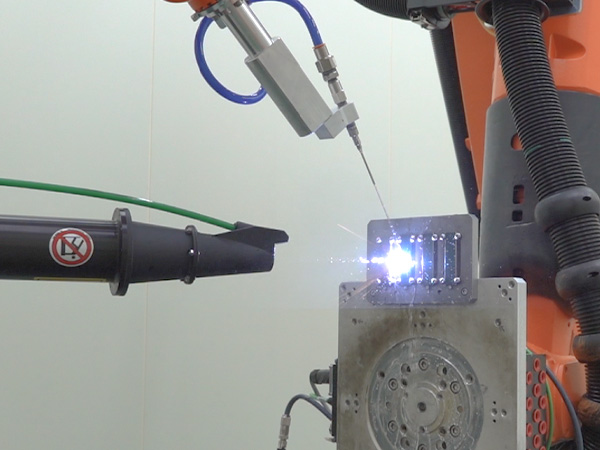

Increase durability

Strengthen

Aircraft

Use laser peening on turbine blades to increase corrosion resistance

Deburr

Remove

Bearings

Use barrel polishing on thin-walled/small parts to remove burrs

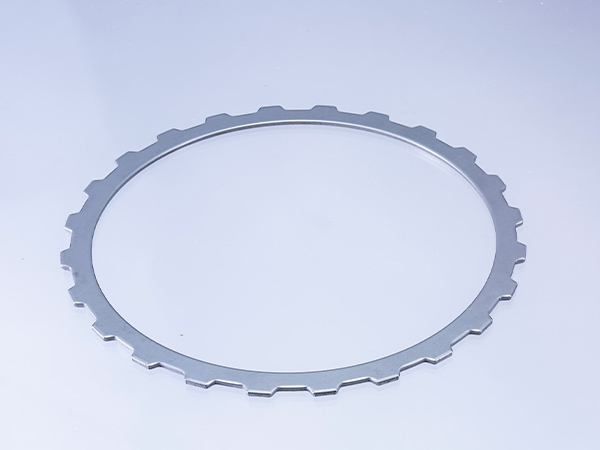

Reduce foundry defects

Roughen

Diecasting

Form dimples on diecast dies to reduce defects

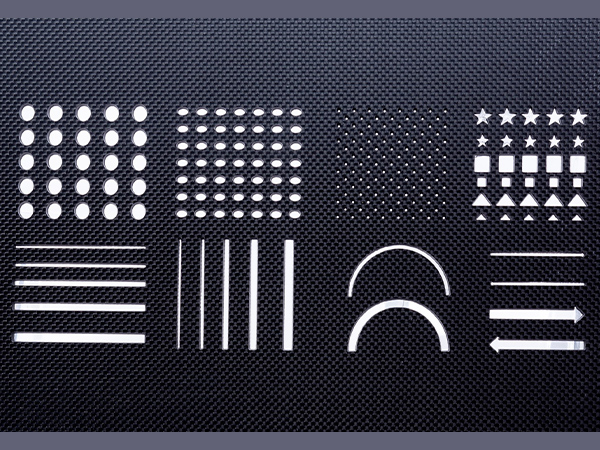

Form carbon fiber

Microprocessing

Aircraft

Use microblasting on CFRPs for patterning processing

Create smooth motion

Polish

Healthcare

Smooth-polish artificial joints to improve sliding performance

Measure surfaces

See

Test/measure

Use contactless measurement to assess surface roughness and 3D shape

Please consult us for inquiries.

+81-52-581-6896

Available hours: 9:00-12:00 and 13:00-17:00 JST, Monday through Friday

(excluding national and corporate holidays)