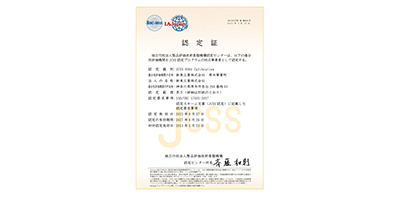

JCSS Calibration Service

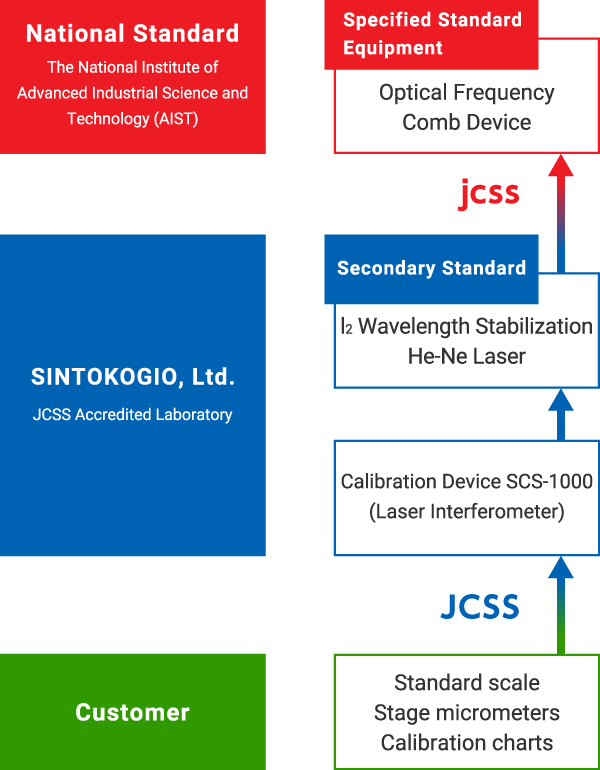

Sintokogio’s Atsugi Division is JCSS-accredited for international MRA in the "length" category and performs JCSS calibration of various measuring instruments in conformance with ISO/IEC 17025.

We are accredited under the Japan Calibration Service System (JCSS), which uses ISO/IEC 17025 as its accreditation standard and operates an accreditation scheme in accordance with ISO/IEC 17011.

The accreditation body that operates JCSS (IAJapan) is a signatory to the mutual recognition of the Asia-Pacific Accreditation Cooperation (APAC) and the International Laboratory Accreditation Cooperation (ILAC).

Sinto is a JCSS-certified business for international MRA compliance. Our certification identification is JCSS 0304 Calibration.

Advantages of Calibrating Measuring Instruments and Measuring Machines at Sinto

Advantage①

Establish traceability to measuring instruments that meet national and international standards

By having Sintokogio calibrate your measuring instruments and measuring equipment, you can ensure traceability to national and international standards, making your measurement results more trustworthy.

Advantage②

Conform to ISO 9001

Use our accredited calibration as part of your ISO 9001 Quality Management System.

Advantage③

Support for automotive industry standard quality systems

We issue calibration certificates as required by IATF 16949, the international standard for quality management systems for the automotive industry.

Advantage④

Establish international trust

Since our calibration is compliant with the Mutual Recognition of Accreditation (MRA), the quality of JCSS calibration is trusted by our international customers as well.

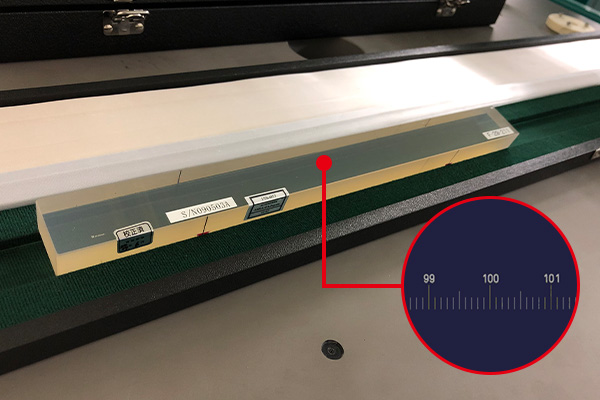

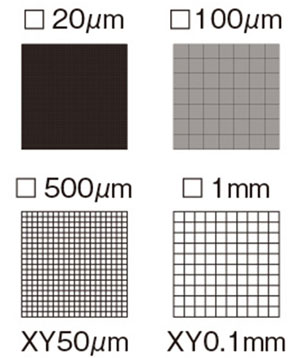

Measuring Instruments and Machines Covered by Sintoʼs JCSS Calibration Service

| Field | Length | ||

|---|---|---|---|

| Scope Category | Laser Wavelength | Length Measuring Instrument | Dimensional Measuring Instrument |

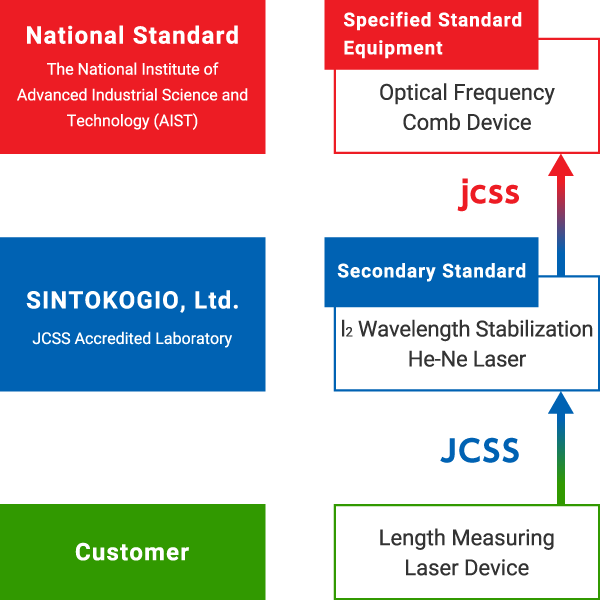

for length measuring He-Ne lasers (633nm)

Sinto offers wavelength calibration services for length measuring He-Ne lasers (633nm) as a JCSS accredited laboratory in the field of “length measuring lasers”.

| Scope Category | Calibration Capacity |

|---|---|

| Wavelength of 633nm He-Ne laser | 4.2×10-11 |

*We perform JCSS calibration regardless of the manufacturer.

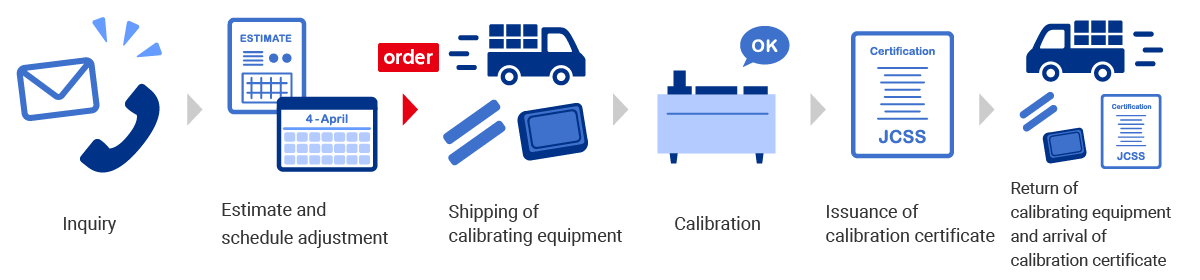

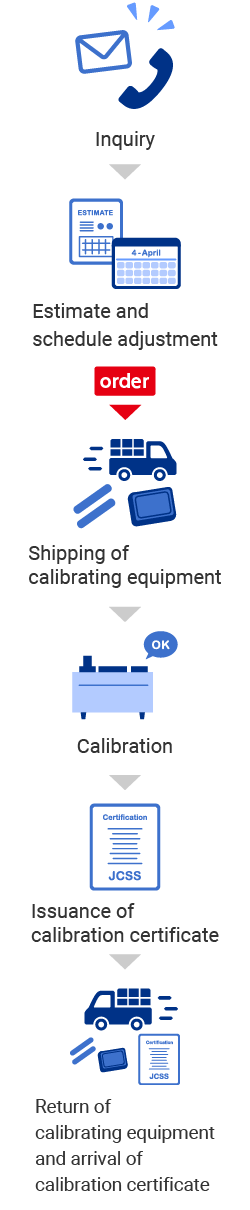

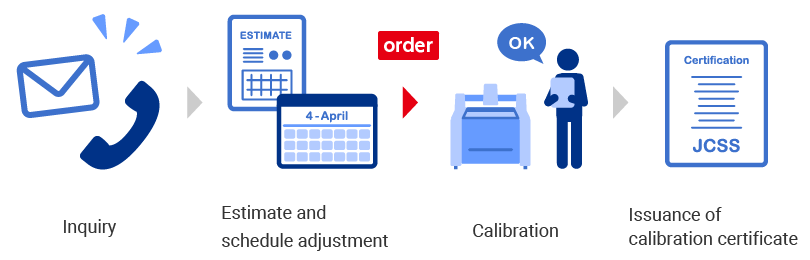

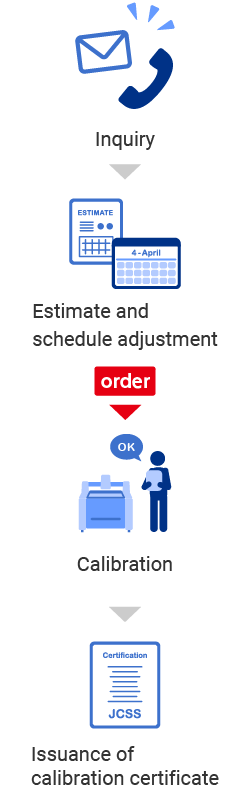

Calibration Service Flow

①Length Measuring Instrument , Dimensional Measuring Instrument

The calibration equipment is sent to us, and then we calibrate it at our company.

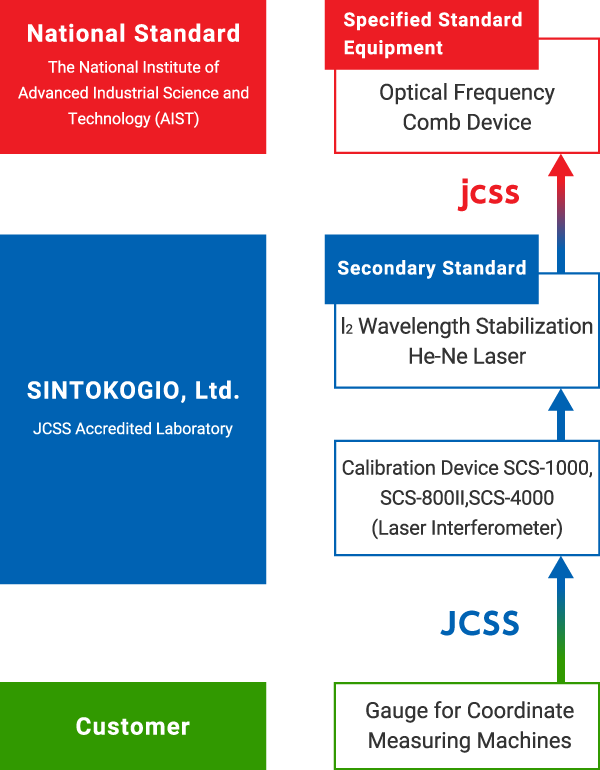

②Coordinate Measuring Machines

Our calibration staff will visit the customer to perform the calibration.

About calibration

Why do measuring instruments need to be calibrated?

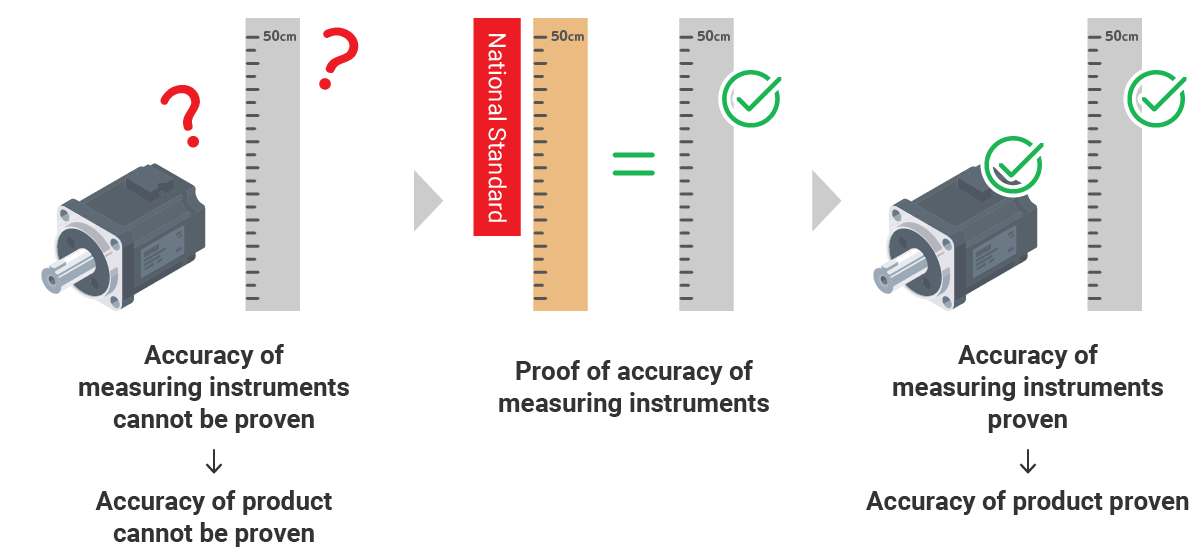

To ensure quality in manufacturing, it is essential to use measuring instruments and measuring machines in the production and inspection process.

However, the values indicated by these measuring instruments and measuring machines are not always accurate. To ensure the accuracy of the measurement results of the instruments and machines used, we must compare these measurement results with the national standards to see how far they deviate.

In recent years, the automotive and aerospace industries have established parts procurement standards to ensure high-quality manufacturing, and these standards include provisions for the calibration of measuring instruments and measuring machines. Therefore, if you are not using measuring instruments that have been calibrated by instruments traced to national standards, you will not be able to meet the specified standards. This will make it difficult to do business with the relevant manufacturers.

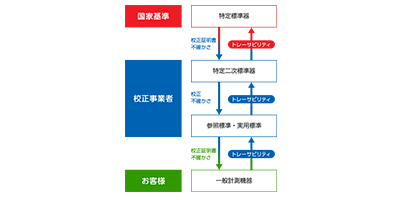

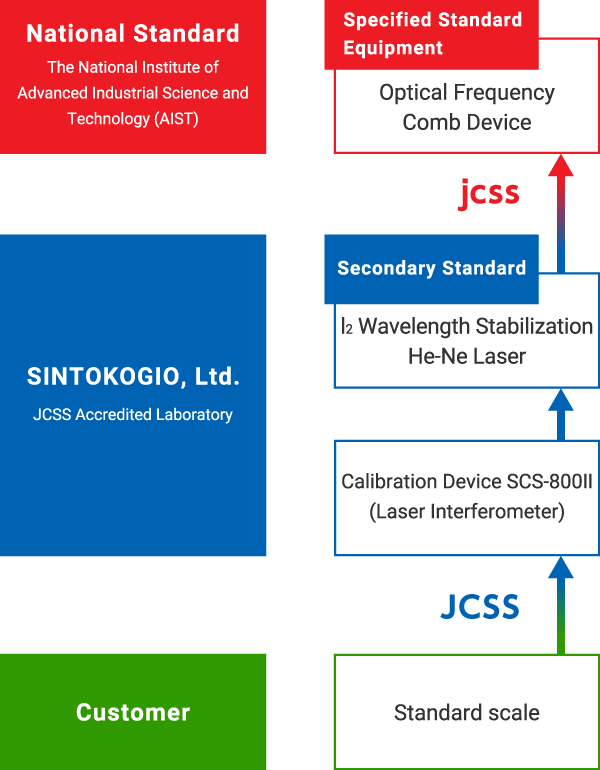

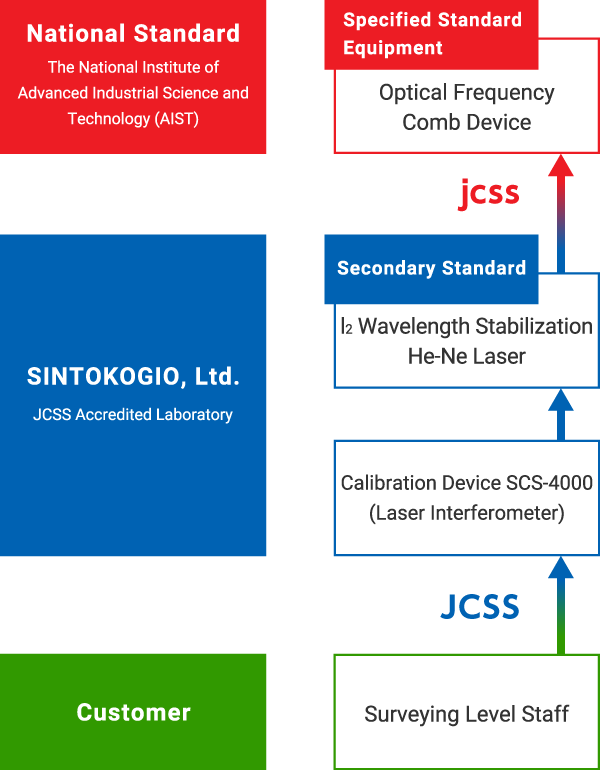

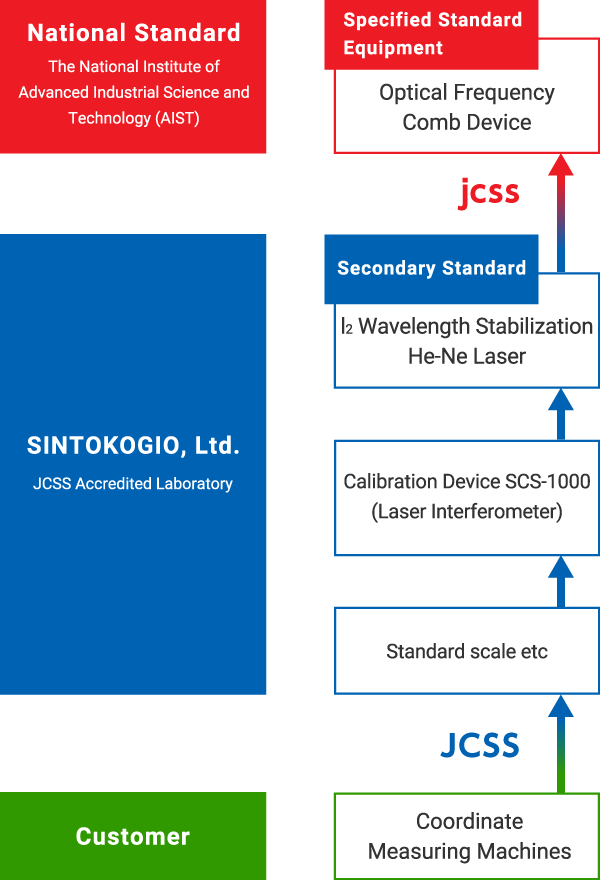

How are the measuring instruments (measuring machines) we normally use calibrated with national standards?

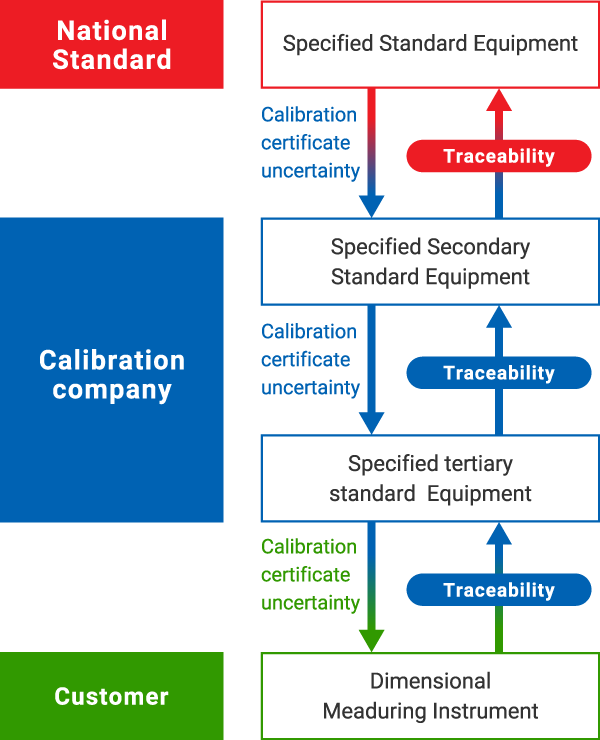

Since national standards are only available in a few designated locations in Japan, it is not possible to directly calibrate the measuring instruments (measuring machines) that we normally use. This is where the concept of "metrological traceability" comes in.

This concept is based on the idea of a measuring instrument (measuring machine) used in day-to-day operations calibrated by a reference measuring instrument (measuring machine), that reference measuring instrument (measuring machine) likewise calibrated by a higher-level reference measuring instrument (measuring machine), and so-on until reaching a national standard. In this case, the measurement result, which states the uncertainty of the measuring instrument (measuring machine) used in day-to-day operations, is traceable to the national standard. A JCSS calibration certificate is required to prove this "metrological traceability.”

Is calibration of measuring instruments and measuring machines the same no matter where I get it done?

What are "JCSS Calibration" and "International MRA"?

There are two types of calibration for measuring instruments and measuring machines: "General Calibration" and "JCSS Calibration". For general calibration, traceability to national standards is ensured at the responsibility of the calibration vendor.

JCSS calibration, on the other hand, is registered under the Measurement Act by the accreditation body (IA Japan) that operates JCSS as a calibration service provider in compliance with ISO/IEC 17025. Calibration certificates bearing the JCSS logo mark can certify that they are traceable to national standards.

In addition, since this accreditation body, IAJapan, is a member of the Asia-Pacific Accreditation Cooperation (APAC) and the International Laboratory Accreditation Cooperation (ILAC) mutual recognition, JCSS calibration laboratories that are accredited under the accreditation international standards become "International MRA-compliant laboratories", and their calibration certificates are accepted globally.

Please consult us for inquiries.

+81-52-581-6896

Available hours: 9:00-12:00 and 13:00-17:00 JST, Monday through Friday

(excluding national and corporate holidays)