Image Processing Measuring Machines

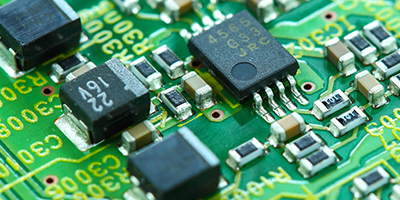

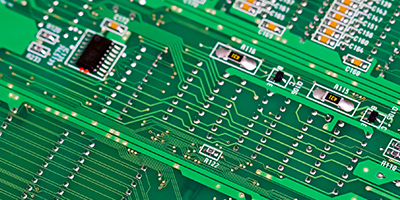

These optical image processing dimension measurement instruments are used in state-of-the-art electronics manufacturing sites for electronic components, flat panel displays, semiconductor-related components, optical communication components, and more.

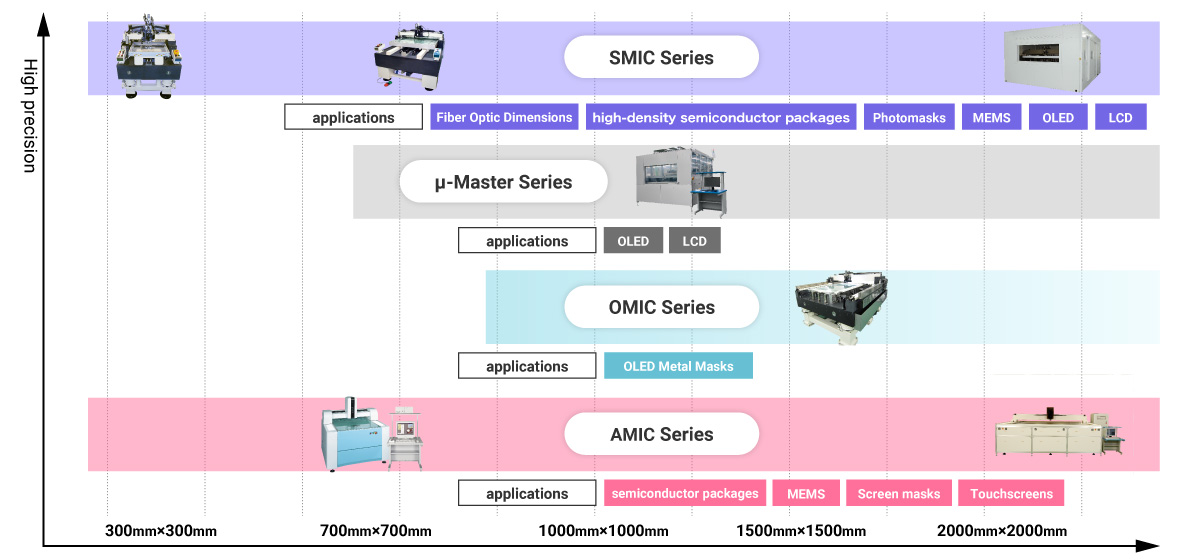

Find an Image Processing Measuring Machine by Size and Accuracy

Image Processing Measuring Machine List

Precision Automatic 2D CMM (Coordinate Measuring Machines)

SMIC Series

Sinto’s premier brand of precision CMM equipment

The SMIC Series - absolute reliability in accuracy, a long history of success. Its photo mask, and precision measuring including OEL,LCD and MEMS demonstrate its capabilities.

SMIC machines are trusted by our customers, making the most of all technologies to make high-precision measurements possible through high precision XY stages thanks to its precise laser interference measurement system and ceramic air slider and granite surface plate, a flat glass table, and highly effective thermal cleaning chamber.

Features

High precision XY stage drive

The perfect non-contact XY stage drive with its low heat-generating linear motor and high hardness ceramic air-slider promises to give high precision results over usage.

Fiber-type laser interferometer

Our in-house created fiber-type laser interferometer. The laser head, a heat source, can be removed from the main body through the fiber transmission, and we are always improving the reliability in our length measurements. The laser wave length is measured and tested with our wave length correction equipment and its quality is guaranteed.

High flatness glass table

Our high flatness double-layered glass tables, with grinded glass maintain a high level of flatness in grain as well as suppress the postural change for the measuring objects and improve accuracy in measurements repeatability.

Efficient thermal clean chambers

The temperature control, equaled at ±0.1℃ in measuring table surface temperature distribution, and at ±0.05℃ in the nozzle, creates a highly precise measurement environment for flat coordinates. The cleanliness of the chamber is maintained below class 100 through the high quality filter.

Product Name

SMIC-300Ⅲ

Explanation

This is the smallest model in the series, which condenses SMIC's elemental technologies into a compact body. It has by far the best hardware design in its class, and it is used for the dimensional measurement of a wide range of products, from optical connectors to photomasks for high-density electronic components.

Main applications

- photomasks for high-density electronic components

- high-density electronic components

- Fiber Optic Dimensions

- microOLED

Specification

| Model | Measurement Range (X,Y) | X,Y Repeatability |

|---|---|---|

| SMIC-300Ⅲ | 300×300mm | 3σ≦0.15μm |

Product Name

SMIC-800ⅢS / 800Ⅲ

Explanation

This best-selling model in the SMIC series is used in a wide range of applications, from OLED and LCD displays for mobile devices such as smartphones to photomasks for next-generation semiconductor package substrates. In recent years, these systems have been adopted as dimensional standards for manufacturing equipment such as exposure systems and lithography systems that enable high-precision manufacturing.

Main applications

- 4.5G OLED/LCD display panels

- Photomasks for next-generation semiconductor packages

- Evaluating accuracy of manufacturing equipment (exposure equipment, lithography equipment, etc.)

Specification

| Model | Measurement Range (X,Y) | X,Y Repeatability |

|---|---|---|

| SMIC-800ⅢS | 800×800mm | 3σ≦0.35μm |

| SMIC-800Ⅲ | 800×960mm | 3σ≦0.35μm |

Product Name

SMIC-SV1100 / SV1300

SV1500 / SV2200

Explanation

The SMIC-SV series is a large SMIC model that supports LCD and OLED display panels from the 5 to 8.5 generation. It fully demonstrates its capabilities in the dimensional measurement of large display panels.

Features

Gantry dual drive

In the large models with their gantry drive, the linear motor and laser interferometry are arranged at right and left sides of the gantry, and they automatically correct the yawing error when driving. Also, Gantry dual drive achieve high-speed drive at 200mm/sec at 2.5nm step as well as guaranteeing straightness in the hard and light ceramic gantry arm.

Main applications

- 5 to 8.5 generation OLED and LCD panels

- Large-size photomasks

Specification

| Model | Measurement Range (X,Y) |

|---|---|

| SMIC-SV1100 | 1100×1300mm |

| SMIC-SV1300 | 1300×1500mm |

| SMIC-SV1500 | 1500×1850mm |

| SMIC-SV2200 | 2200×2500mm |

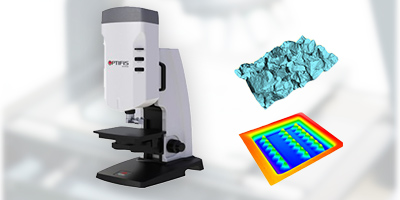

Automatic CD Measuring machine

µ-Master Series

Dedicated Model for Short Dimension Measurement

This model is designed for measurement of short dimensions such as CD or overlay measurement in TFT array processes for OLED and LCD display panels. Measurement of LTPS and state-of-the-art LTPO TFT2 micro patterns are fully supported by our advanced stage positioning technology cultivated for precision coordinate measuring machines, high-resolution optical microscopes, and advanced custom measurement software tools.

This model also supports the measurement of the lamination fit between TFT and color filter (CF) in the cell process, as well as the line width measurement of photomasks.

*1 LTPS: Low Temperature Polycrystalline Silicon TFT

*2 LTPO: Low Temperature Polycrystalline Oxide TFT

Features

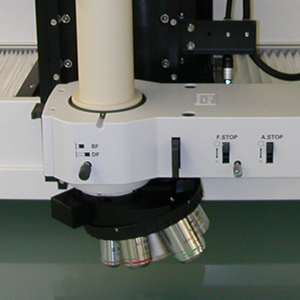

High Resolution Microscope

This system is equipped with Sinto’s high-resolution optical microscope that achieves consistent accuracy in line width measurement at the micron level and enables measurement of CD and overlay for fine LTPS and LTPO TFTs. Other variations include revolving microscope specifications for a wide range of measurements, and color CCD specifications for observation of color filters and OLED panels.

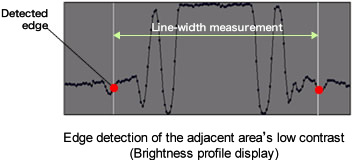

Original edge detection algorithm

With Original edge detection algorithm, previously impossible to detect edges, like those in areas where the layers are arranged in a complex adjacent configuration, or low contrast edges, can be accurately detected. This is an indispensable tool for dealing with the continual miniaturization of the TFT array process with LTPS and the like.

Takt Time Reduction Functions

Measurement takt time can be minimized by functions such as real-time focus enabled by laser autofocus, measurement position learning, and automatic settings for the shortest route.

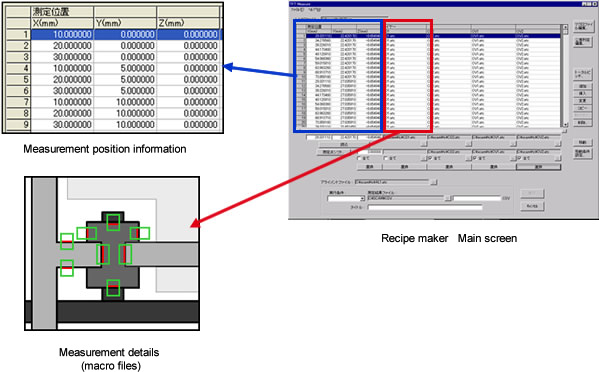

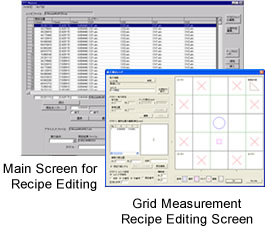

Streamlining recipe creation

Measurement recipes created with the “Measurement recipe creation / edit support software / recipe maker” consists of “measurement position information” and “measurement macro files” where detail measurement contents are described, and both can be combined as you wish, and each easily can be compiled in various ways.

Particularly for the TFT array process in which multiple layers are stacked in the same position, you can drastically increase the efficiency of recipe creation by changing the existing recipes into other layer recipes by changing the contents of the “measurement macro files” without changing the “measurement position information”.

Product Name

Automatic CD Measuring machine

µ-Master

Main applications

- LCD/OLED display panels

- Photomasks

- Various fine line width substrates

Specification

| Model | Measurement Range (X,Y) | X,Y Repeatability |

|---|---|---|

| μ-M800 | 730×920mm | 3σ≦30nm |

| μ-M1100 | 1100×1300mm | |

| μ-M1300 | 1300×1500mm | |

| μ-M1500 | 1500×1850mm | |

| μ-M2300 | 2300×2600mm |

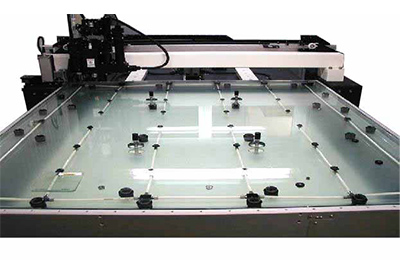

2D CMM for OLED Metal Masks

OMIC Series

Custom Models Supporting OLED vapor deposition Fine Metal Masks

OLED displays have a wide range of applications, from smartphones, tablets, and TVs to smartwatches and smart glasses for AR/VR. The OMIC series is specifically designed to meet the dimensional measurement requirements of metal masks mainly used in the deposition process for OLED panels. Our two standard models support the G6h size, which is the mainstream for mass production of OLED panels.

(We have experience in other sizes as well. Please contact us for more information.)

Product Name

2D CMM for OLED Metal Masks

OMIC-SV 1500/1500

Explanation

The OMIC-SV 1500 uses a ceramic air slider, laser interferometry system, and thermal clean chamber for the high-precision measurement of pixel positional accuracy (PPA), pixel size, and flatness (optional) of fine metal masks, which are used for deposition of increasingly high-definition RGB emission layers.

The OMIC-1500 supports aperture position, size, and flatness measurement (optional) of open metal masks used for common layer deposition and encapsulation layer CVD.

Main applications

- OLED Vapor deposition Fine Metal Masks

Specification

| Model | Measurement Range (X,Y) | Short dimension repeatability |

|---|---|---|

| OMIC-SV1500 | 1100×1700mm | 3σ≦0.35µm |

| OMIC-1500 | 1100×1700mm | 3σ≦1µm |

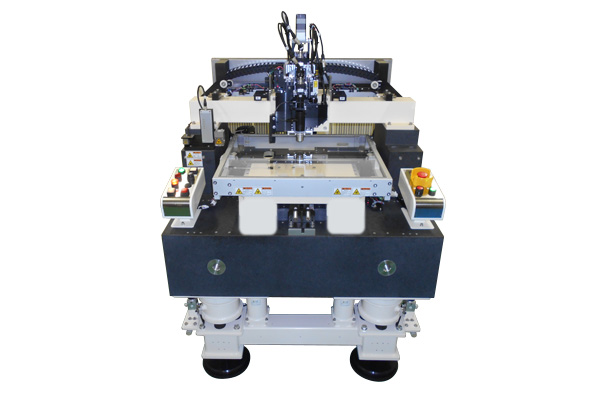

Automatic 2D/3D CMM

AMIC Series

Our Standard Series for Dimensional Control in a Wide Range of Fields

This is Sinto's standard series, used in dimensional control in a wide range of fields, from small semiconductor package components and high-density electronic components to large FPD panels.

AMIC, born from a precise mechanical design in pursuit of the true meaning of precision, has been trusted and used in R&D and manufacturing for many years.

Product Name

Automatic 2D/3D CMM

AMIC-360/710/810

Explanation

AMIC-AMIC-360 is a compact model ideal for dimensional control of fine-patterned semiconductor package components.

AMIC-710 is the best-selling model of the AMIC series, trusted by users for a wide range of measurements from electronic components such as high-density PCBs and MLCCs to film/screen/metal masks used in their manufacturing processes. Elemental technologies such as the cast-iron housing, high straightness linear guide, and center drive mechanism make the AMIC stand out.

Main applications

- IC Packages

- high-density PCBs

- MLCCs

- Touchscreens

- MicroOLED

- FPD panels

- Film masks

- Screen masks

- Metal masks

Specification

| Model | Measurement Range (X,Y),(Z) | X,Y Repeatability |

|---|---|---|

| AMIC-360 | 360×360(×60)mm | 3σ≦0.7μm |

| AMIC-710 | 700×800(×100)mm | 3σ≦0.9μm |

| AMIC-810 | 740×930(×100)mm | 3σ≦0.9μm |

| AMIC-811HA | 740×930(×100)mm | 3σ≦0.5μm |

Product Name

Automatic 2D/3D CMM

AMIC Series

Explanation

Even in large areas of 1000 mm or more, high XY stage performance is maintained. Our highly dependable XY measurement coordinate system is created combining the main unit, featuring a dual linear motor drive and table flatness adjustment mechanism to maintain performance, with sophisticated correction technology.

Main applications

- FPD panels

- FPD bare glass

- Alignment Film Printing Plate

- Screen masks

- Metal masks

Specification

| Model | Measurement Range (X,Y),(Z) | X,Y Repeatability |

|---|---|---|

| AMIC-1100 | 1100×1300(×60)mm | 3σ≦2.0μm |

| AMIC-1710 | 1900×1700(×100)mm | 3σ≦2.5μm |

| AMIC-2600 | 2600×2250(×100)mm | 3σ≦3.5μm |

AMIC Series Hardware Options

These options are available for the AMIC series.

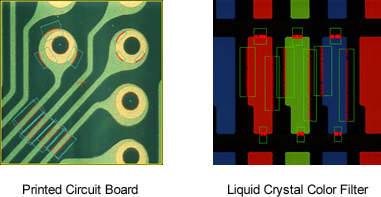

Color Image Processing

By applying grayscale image processing to each RGB color on an image, it is possible to detect edges that are hard to discern in a monochromatic image.

In addition, it can be used to do surface observations in color as well as image sampling.

Revolving microscope

Up to 5 types of objective lenses can be mounted on this microscope’s revolving nosepiece. It can support a wide variety of uses, from detailed pattern measurements made from high-density images to surface observations made from wide viewing angles.

Wide-field Microscope

In combination with the standard high/low 2-variation microscope, a wide-field microscope can be added for alignment and observation.

Height Measurement Sensor

Additional optional specifications can be added to suit the application, such as a laser displacement gauge for height and shape measurement.

* Not available for some models.

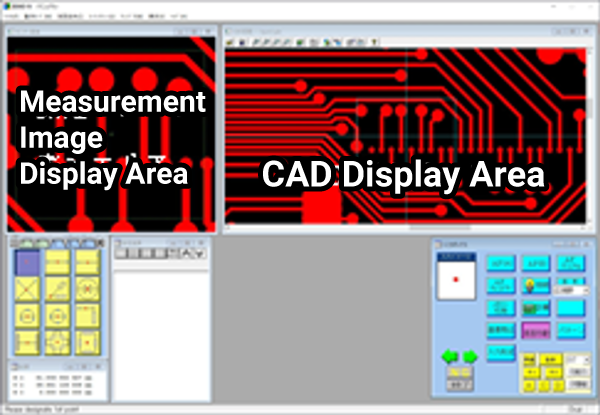

Image Measurement Software

3D-SCAM

Measurement software 3D-SCAM that have been adopted to all series is equipped with features that respond to high-level operability and measurement of varied objects to support the customer’s measurement.

Basic Functions

Customizable Measurement Mode

Equipped with Measurement Mode and Alignment Mode that can respond to measurements of any shape and dimensions. Furthermore, we will respond to customers’ demands by creating new modes.

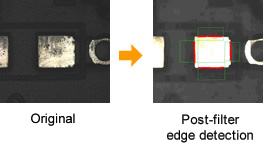

Image Filter

With image filters for enlargement, reduction, median, etc., the edges of even images with a lot of noise such as burrs and scratches, or low-contrast images, are accurately detected.

Automatic Image-Saving Function

This function automatically saves the image in the process of measurement. You can choose settings like “Save All Images,” “Save Only When Encountering Errors,” etc, check image of the error point after end of measurement even if you are apart from the machine during automatic measurement.

Digital Zoom Function

32 levels of digital zoom, with 8x as the maximum, can be displayed. Using this, you can adeptly indicate measurement positions even on minute parts.

Auto Review Function

Any measurement data can be indicated from the results display window, and a microscope can be moved to that location.

Teaching Macro Edit

Not only various measurement conditions such as lighting, auto-focus, and image filters, but also measurement position coordinates, edge detection box configuration, etc. can be edited, and the measurement program can be changed to respond to work conditions.

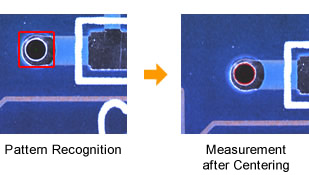

Pattern Matching

By detecting pattern that had been registered in advance within the field of the image, position shift caused from sample settings or deviation from design value can be canceled.

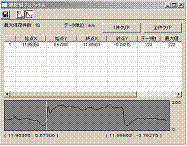

Brightness Profile Display

The brightness profile can be displayed at any point on screen, and edge information can be numerically managed rather than the customer having to rely simply on appearance.

Option software

To respond to the management needs that come along with the new processes born out of technological innovation, we have included intelligent software options.

Recipe Maker Measurement Recipe Creation/Edit Support Software

Measurement recipes drawn up on the Recipe Maker are comprised of “measurement location information” and “measurement macro files” that describe measurement contents. These can easily be combined or edited separately.

With features like loading measurement coordinates from text data and substitution of measurement points, as well as designation of measurement position on graphic display, this is indispensable software for production sites that manage and edit many recipes.

C-AutoOffline CAD Teaching Software

You can prepare an automatic measurement program based on CAD data before producing the work, and do the measurement as soon as the work is complete. Because the operation procedures are identical to the 3D-SCAM measurement software installed in machine, there is no need to learn new procedures from scratch.

The CAD format supports DXF, Garber, etc., as well as NC data for drill machines.

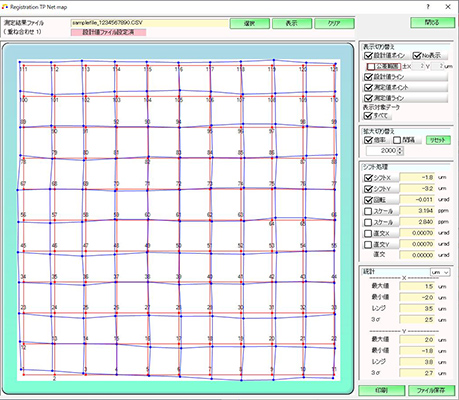

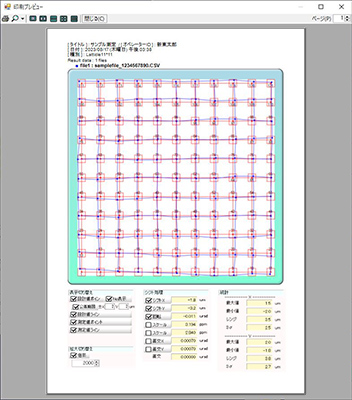

Registration TP(registration analysis software)

This optional software package is perfect for evaluating registration accuracy. The pattern positional accuracy of a grid pattern on a photomask can be compared with the design values and analyzed using rotational, linear, orthogonal, shift, and other indices. The graphical display can be used for analysis of numerical values as well as trends, and it can also be used as data for reports.

Please consult us for inquiries.

+81-52-581-6896

Available hours: 9:00-12:00 and 13:00-17:00 JST, Monday through Friday

(excluding national and corporate holidays)