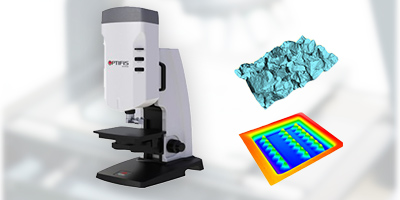

White Light Interferometric Microscope

Non-contact measurement using white light interferometry enables surface profile, height (step), and roughness measurement with both a wide field of view and high resolution.

Advantages and Features of 3D Shape Measurement Using White Light Interferometry

Since the resolution of height measurement does not depend on optical resolution, height (step) and roughness measurements can be made with 1 nm resolution over a wide measurement range.

Profile Window

The profile window displays a cross-sectional profile on the line indicated in the 2D display image. The profile window allows analysis of all dimensions including length, average height, and maximum and minimum heights, and it includes a tilt correction function (approximate straight line/two-point tilt/curve/circle).

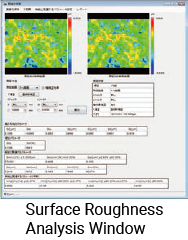

Surface Roughness Analysis

This window is used to calculate and display surface roughness. The analysis conforms to the new JIS B0681-2 roughness standard. This gives an accurate roughness analysis based on surface information that cannot be evaluated using contact-type measuring machines.

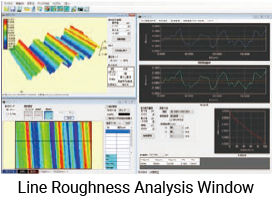

Linear Roughness Analysis

This window is used to calculate and display surface roughness. Roughness parameters are supported in accordance with JIS B0601:2001/2013.

Product Name

White Light Interferometric Microscope

IS-R100

IS-R100

Explanation

Non-contact measurement using white light interferometry enables surface profile, height (step), and roughness measurement with both a wide field of view and high resolution. The system has an abundance of analysis functions for acquired 3D data and can be used for a wide range of applications from measurement to observation and analysis. In addition to the conventional line roughness evaluation, it also supports the latest JIS B0681-2 surface roughness measurement. This white light interference microscope is ideal for surface roughness evaluation of precision micro-machined and smoothly polished parts.

Specification

Standard System

| Maximum object size | (H: 116mm at 5x objective lens, 85mm at 2.5x objective lens) |

|---|---|

| Effective measurement range | X: 75 × Y: 50mm Z1 axis (focusing unit): 30mm

Z2 axis (microscope height adjustable stroke): 90mm Z3 axis (piezo drive): 250μm (option: 400μm) |

| Precision XY stage | Manual |

| Microscope | Single mount microscope |

| Objective lens | Choose from the following six:2.5×,5×,10×,20×,50×,100× |

| Field of vision | H:7.00 × V:5.00mm ~ H:0.17 × V:0.12mm |

| Lighting | Coaxial epi-illumination (white LED) |

| Anti-vibration mechanism | Passive anti-vibration table (optional: active anti-vibration table) |

3D shape measurement (white light interferometry)

| Vertical resolution | Vertical scanning method: 1nm / Phase shift method: 0.1nm |

|---|---|

| Step measurement repeatability | σ≦0.5%*1 |

*1 When inspected at VLSI's 8μm standard step. Based on our measurement conditions.

Please consult us for inquiries.

+81-52-581-6896

Available hours: 9:00-12:00 and 13:00-17:00 JST, Monday through Friday

(excluding national and corporate holidays)